How Is an Electric Car Battery Made

Electric car batteries are complex marvels of modern engineering, built from rare materials and precision processes. From mining lithium to assembling battery packs, every step ensures safety, efficiency, and long life. Understanding how an electric car battery is made reveals the innovation behind clean transportation.

In This Article

- 1 Key Takeaways

- 2 📑 Table of Contents

- 3 Introduction: The Heart of the Electric Vehicle

- 4 From the Earth to the Factory: Sourcing Raw Materials

- 5 Building the Battery Cell: The Core of the Process

- 6 From Cell to Pack: Assembling the Full Battery

- 7 The Role of Automation and Quality Control

- 8 Sustainability and the Future of Battery Production

- 9 Conclusion: A Complex Journey with a Clean Future

- 10 Frequently Asked Questions

Key Takeaways

- Raw materials like lithium, cobalt, and nickel are essential: These elements form the core of lithium-ion batteries, enabling high energy density and rechargeability.

- Battery cells are built in cleanroom environments: Precision and contamination control are critical during electrode coating and assembly.

- The manufacturing process includes multiple stages: From slurry mixing to formation cycling, each step ensures performance and safety.

- Battery management systems (BMS) monitor performance: These electronic systems protect the battery from overcharging, overheating, and imbalance.

- Recycling and sustainability are growing priorities: As EV adoption rises, so does the focus on reusing materials and reducing environmental impact.

- Automation plays a major role in production: Robots and AI-driven systems improve consistency, speed, and quality control.

- Quality testing is rigorous and ongoing: Every battery pack undergoes extensive checks before installation in vehicles.

📑 Table of Contents

- Introduction: The Heart of the Electric Vehicle

- From the Earth to the Factory: Sourcing Raw Materials

- Building the Battery Cell: The Core of the Process

- From Cell to Pack: Assembling the Full Battery

- The Role of Automation and Quality Control

- Sustainability and the Future of Battery Production

- Conclusion: A Complex Journey with a Clean Future

Introduction: The Heart of the Electric Vehicle

Imagine driving a car that hums quietly down the road, emits no exhaust, and runs entirely on electricity. That’s the promise of electric vehicles (EVs), and at the center of this revolution is one crucial component: the electric car battery. Without it, there’s no power, no range, and no clean driving experience. But have you ever wondered how this powerful, compact energy source is actually made?

The journey of an electric car battery begins long before it’s installed in a vehicle. It starts deep underground, in mines where raw materials are extracted, and continues through highly controlled factories where precision engineering transforms those materials into high-performance energy storage units. The process is a blend of chemistry, physics, and advanced manufacturing—each step carefully designed to deliver safety, efficiency, and longevity. Understanding how an electric car battery is made not only satisfies curiosity but also highlights the innovation driving the future of transportation.

From the Earth to the Factory: Sourcing Raw Materials

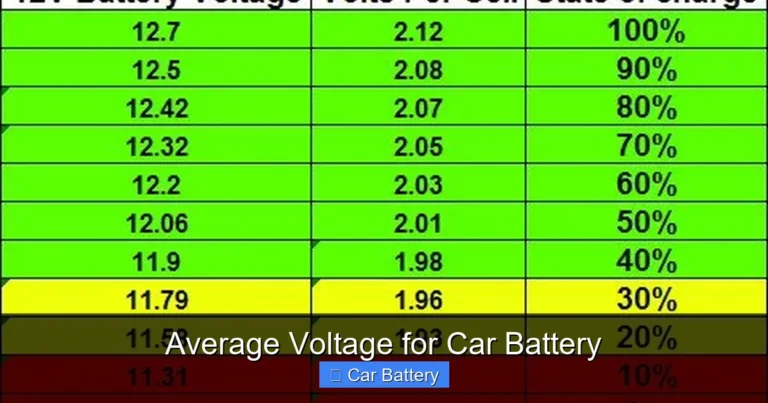

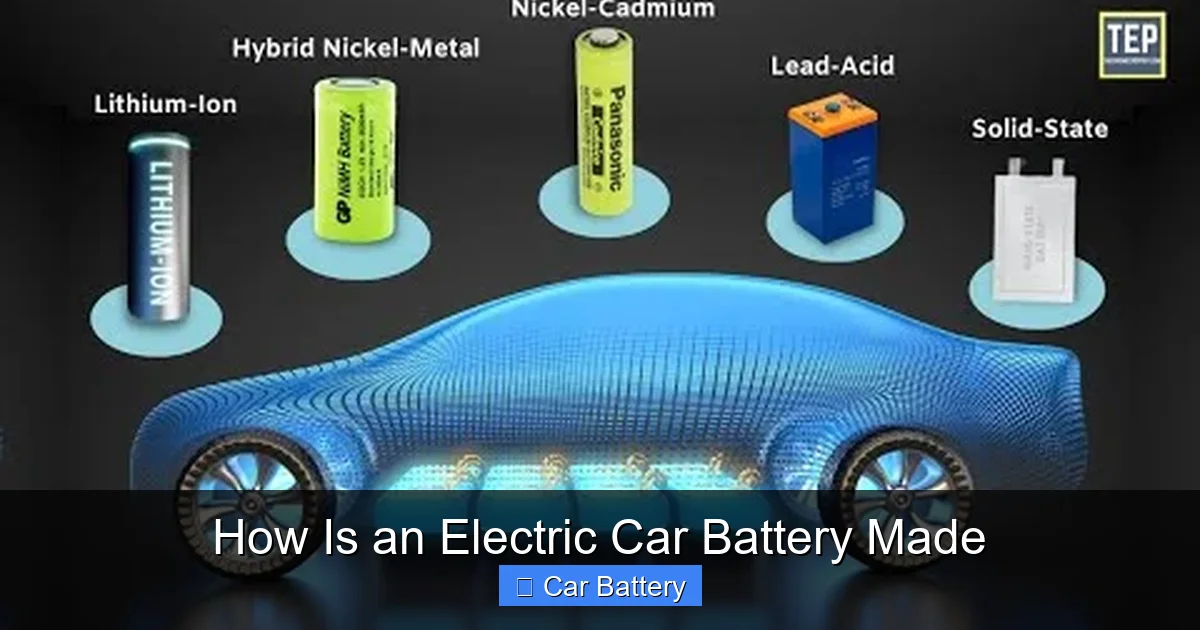

The first step in making an electric car battery is gathering the raw materials. Unlike traditional car batteries that rely on lead and acid, electric car batteries—especially lithium-ion types—depend on a unique mix of minerals. These include lithium, cobalt, nickel, manganese, and graphite. Each plays a vital role in the battery’s chemistry and performance.

Visual guide about How Is an Electric Car Battery Made

Image source: car-images.bauersecure.com

Lithium: The Star of the Show

Lithium is the lightest metal and a key ingredient in rechargeable batteries. It allows ions to move easily between the anode and cathode, enabling efficient charging and discharging. Most lithium today comes from two sources: hard rock mining (like spodumene in Australia) and brine extraction (from salt flats in South America, especially Chile and Argentina). The brine method involves pumping underground saltwater to the surface and evaporating it in large ponds, leaving behind lithium-rich compounds.

Cobalt and Nickel: Power and Stability

Cobalt helps stabilize the battery’s structure and improves its lifespan, while nickel increases energy density—meaning more power in a smaller space. However, cobalt mining has raised ethical and environmental concerns, especially in the Democratic Republic of Congo, where much of the world’s supply comes from. As a result, battery makers are working to reduce cobalt content or find alternatives.

Graphite and Manganese: The Supporting Cast

Graphite is used in the anode (the negative electrode), where lithium ions are stored during charging. Natural graphite comes from mines, while synthetic graphite is made from petroleum coke. Manganese, often used in combination with nickel and cobalt (as in NMC batteries), helps improve thermal stability and safety.

Once these materials are mined and processed, they’re shipped to battery factories around the world. But before they can become part of a battery, they must be refined into high-purity chemicals—like lithium carbonate or nickel sulfate—ready for the next stage.

Building the Battery Cell: The Core of the Process

The heart of an electric car battery is the individual cell. Think of it like a tiny energy sandwich: layers of materials stacked together to store and release electricity. Most EV batteries use cylindrical, prismatic, or pouch-shaped cells, with cylindrical cells (like Tesla’s 4680) being popular for their strength and efficiency.

Visual guide about How Is an Electric Car Battery Made

Image source: i.ytimg.com

Creating the Electrodes: Anode and Cathode

The anode and cathode are the two main electrodes in a battery. The cathode is typically made from a mix of lithium, nickel, cobalt, and manganese (NMC), while the anode is usually graphite. To make these, manufacturers start by mixing the raw materials into a thick paste called a slurry.

This slurry is then coated onto thin metal foils—aluminum for the cathode and copper for the anode. The coated foils are dried in large ovens to remove solvents, then compressed to ensure even thickness and density. This step is crucial: if the coating is uneven, the battery may not charge properly or could overheat.

Assembling the Cell: Precision in a Cleanroom

Once the electrodes are ready, they’re assembled into cells in a cleanroom environment—similar to those used in semiconductor manufacturing. Even a speck of dust can cause a short circuit, so air filtration and worker suits are standard.

The process involves stacking or winding the anode, separator, and cathode into a tight roll (for cylindrical cells) or layered sheets (for prismatic or pouch cells). A separator—a thin, porous plastic film—sits between the anode and cathode to prevent direct contact while allowing lithium ions to pass through.

After assembly, the cell is filled with electrolyte, a liquid that enables ion movement. This is done in a vacuum to ensure complete saturation. Finally, the cell is sealed and undergoes initial charging, a process called “formation,” which activates the battery and forms a protective layer on the anode.

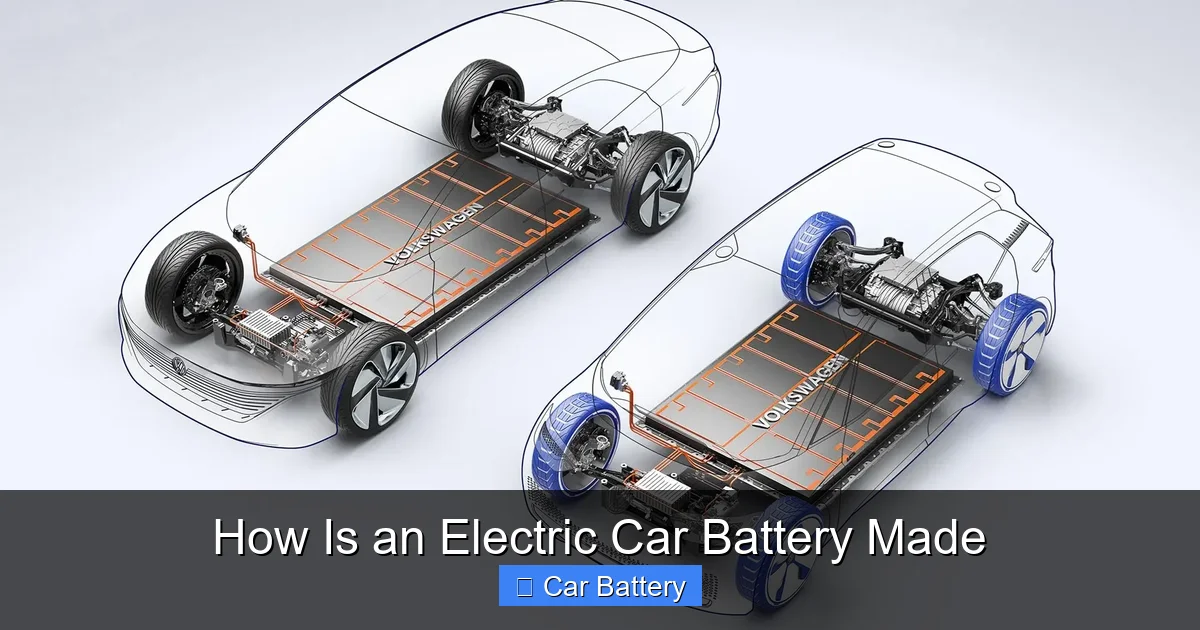

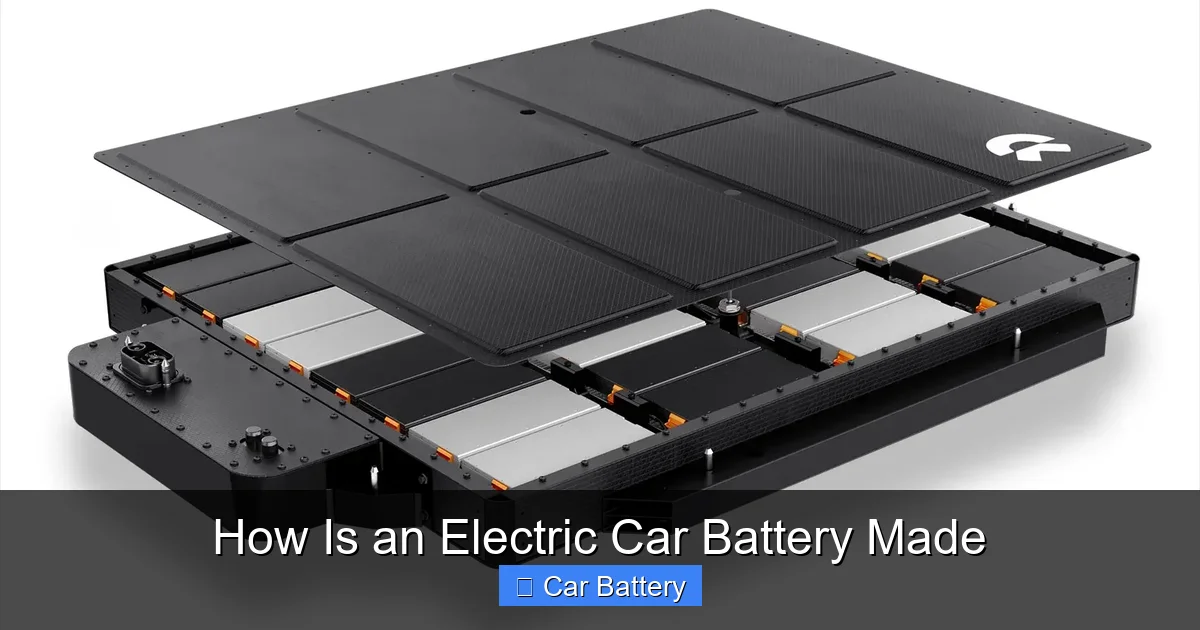

From Cell to Pack: Assembling the Full Battery

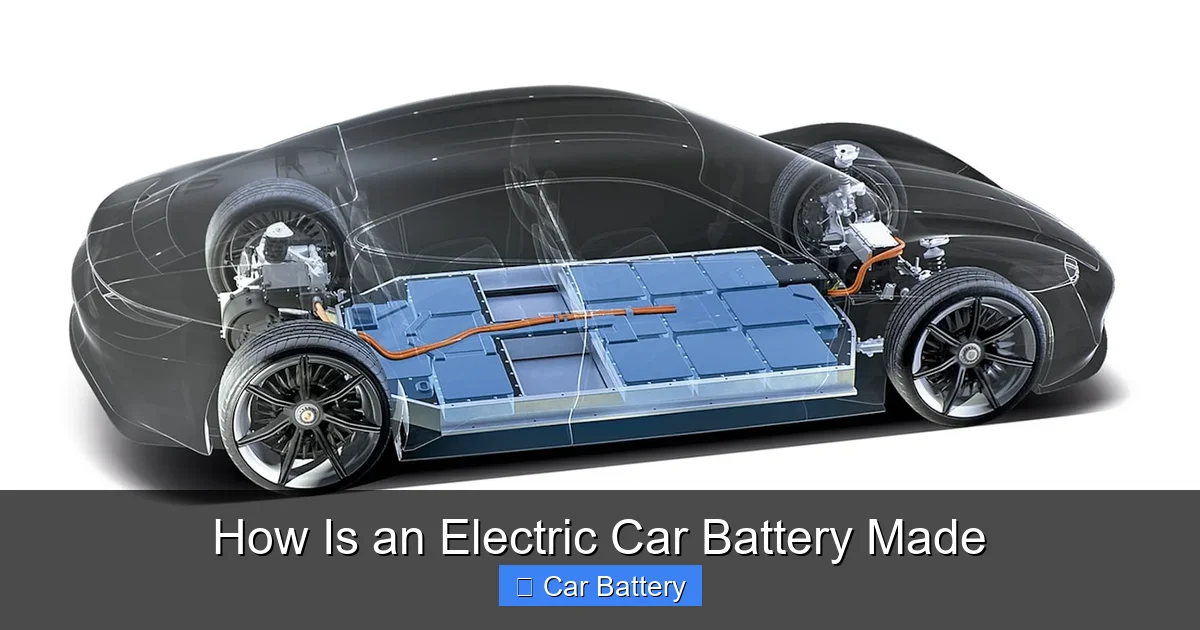

A single battery cell isn’t powerful enough to run a car. That’s why hundreds or even thousands of cells are combined into modules, and modules are grouped into a complete battery pack. This pack is what you’ll find under the floor of most electric vehicles.

Visual guide about How Is an Electric Car Battery Made

Image source: fnnewsonline.com

Module Assembly: Connecting the Cells

Cells are connected in series and parallel configurations to achieve the desired voltage and capacity. For example, a typical EV battery might have 96 cells in series to reach 400 volts. These connections are made using laser welding or ultrasonic bonding to ensure low resistance and durability.

Each module includes cooling plates, sensors, and structural supports. Cooling is essential—batteries generate heat during charging and discharging, and overheating can reduce performance or cause safety issues. Most EVs use liquid cooling systems that circulate coolant through channels near the cells.

The Battery Pack: Integration and Protection

The final battery pack is a robust, sealed unit designed to withstand vibration, temperature changes, and impacts. It includes a metal or composite casing, electrical connectors, and a battery management system (BMS). The BMS is like the brain of the battery—it monitors voltage, temperature, and state of charge for each cell, balancing them to prevent overcharging or deep discharging.

The pack is also equipped with safety features like fuses, disconnectors, and pressure vents. In the event of a crash or malfunction, these systems can isolate the battery or release pressure to prevent fires.

The Role of Automation and Quality Control

Making electric car batteries at scale requires incredible precision and consistency. That’s why automation plays a huge role in modern battery factories. Robots handle everything from mixing slurries to welding cells, reducing human error and increasing production speed.

AI and Machine Learning in Manufacturing

Advanced factories use AI to monitor every step of the process. Sensors collect data on temperature, pressure, and chemical composition in real time. Machine learning algorithms analyze this data to detect anomalies, predict failures, and optimize performance. For example, if a coating machine starts to drift out of tolerance, the system can flag it before defective cells are produced.

Rigorous Testing for Safety and Performance

Every battery pack undergoes extensive testing before it leaves the factory. This includes electrical tests (like capacity and resistance checks), thermal tests (exposing the battery to extreme heat and cold), and mechanical tests (simulating crashes and vibrations). Some manufacturers even perform nail penetration tests to see how the battery reacts to physical damage.

Only after passing all these tests is a battery approved for use in a vehicle. This level of scrutiny ensures that EVs are safe, reliable, and built to last—often with warranties covering 8 years or 100,000 miles.

Sustainability and the Future of Battery Production

As electric vehicles become more popular, so does the need for sustainable battery production. Mining raw materials can have environmental and social impacts, and battery waste is a growing concern. That’s why the industry is focusing on recycling, reducing material use, and improving efficiency.

Battery Recycling: Closing the Loop

Recycling electric car batteries is becoming more common. Companies like Redwood Materials and Li-Cycle are developing processes to recover up to 95% of materials like lithium, cobalt, and nickel. These materials can then be reused in new batteries, reducing the need for mining.

Recycling typically involves shredding the battery, separating the components, and using hydrometallurgy or pyrometallurgy to extract valuable metals. While still evolving, recycling is expected to play a major role in the circular economy of EVs.

Solid-State Batteries: The Next Frontier

Researchers are also working on next-generation batteries, like solid-state batteries, which replace the liquid electrolyte with a solid material. These promise higher energy density, faster charging, and improved safety. Companies like Toyota and QuantumScape are investing heavily in this technology, though mass production is still a few years away.

Other innovations include silicon anodes (which can store more lithium than graphite) and cobalt-free chemistries (like lithium iron phosphate, or LFP), which are already being used in some EVs for their lower cost and longer life.

Conclusion: A Complex Journey with a Clean Future

The process of how an electric car battery is made is a remarkable blend of science, engineering, and sustainability. From mining rare minerals to assembling high-tech packs in spotless factories, every step is designed to deliver clean, reliable power for the vehicles of tomorrow. While challenges remain—like ethical sourcing and recycling infrastructure—the industry is making steady progress.

As battery technology improves and production scales up, electric vehicles will become more affordable, efficient, and accessible. Understanding the journey of an electric car battery not only deepens appreciation for the technology but also highlights the importance of responsible innovation. The future of transportation is electric, and it all starts with the battery.

Frequently Asked Questions

What materials are used in electric car batteries?

Electric car batteries primarily use lithium, cobalt, nickel, manganese, and graphite. These materials form the electrodes and electrolyte in lithium-ion batteries, enabling high energy density and rechargeability.

How long does it take to make an electric car battery?

The entire process—from raw material processing to final assembly—can take several weeks. However, the actual cell manufacturing and pack assembly in a factory typically take just a few days.

Are electric car batteries safe?

Yes, modern electric car batteries are designed with multiple safety features, including thermal management, battery management systems, and protective casings. Rigorous testing ensures they can withstand crashes, overheating, and other stresses.

Can electric car batteries be recycled?

Yes, electric car batteries can be recycled to recover valuable materials like lithium, cobalt, and nickel. Recycling rates are improving, and many companies are building facilities to support a circular battery economy.

What is a battery management system (BMS)?

A BMS is an electronic system that monitors and manages the battery’s performance. It tracks voltage, temperature, and charge levels, balances cells, and protects against overcharging or overheating.

How do manufacturers ensure battery quality?

Manufacturers use automation, real-time monitoring, and extensive testing—including electrical, thermal, and mechanical tests—to ensure every battery meets strict safety and performance standards before installation.