How to Lubricate a Lippert Slide Out

Keeping your Lippert slide out properly lubricated is essential for smooth operation, longevity, and preventing costly repairs. This guide walks you through the entire process—from identifying the right lubrication points to choosing the best products and maintaining your system year-round.

In This Article

- 1 Key Takeaways

- 2 📑 Table of Contents

- 3 Why Lubricating Your Lippert Slide Out Matters

- 4 Understanding Your Lippert Slide Out System

- 5 Choosing the Right Lubricant for Your Slide Out

- 6 Step-by-Step Guide to Lubricating Your Lippert Slide Out

- 7 Maintenance Schedule and Best Practices

- 8 Troubleshooting Common Slide-Out Problems

- 9 Conclusion

- 10 Frequently Asked Questions

Key Takeaways

- Regular lubrication prevents wear and tear: Properly greasing your Lippert slide out reduces friction, extends component life, and avoids binding or jerky movements.

- Use only RV-safe, non-petroleum-based lubricants: Products like silicone spray or PTFE-based greases are ideal—avoid WD-40 or heavy grease that can attract dirt.

- Lubricate key components: Focus on the rack and pinion, roller tracks, gearboxes, and pivot points for optimal performance.

- Clean before you lube: Always remove dirt, debris, and old grease to ensure new lubricant works effectively.

- Inspect for damage during maintenance: Look for worn rollers, bent tracks, or loose bolts—early detection saves money.

- Follow a seasonal schedule: Lubricate every 3–6 months or after heavy use, especially before winter storage.

- Refer to your owner’s manual: Lippert models vary slightly—always check model-specific instructions for best results.

📑 Table of Contents

Why Lubricating Your Lippert Slide Out Matters

If you own an RV with a slide-out room, you know how much it enhances your living space. Whether it’s a bedroom, kitchen, or living area, that extra room makes all the difference on long trips or weekend getaways. But like any mechanical system, slide-outs need regular care—and one of the most important maintenance tasks is lubrication.

Lippert Components is one of the leading manufacturers of RV slide-out systems in North America. Their systems are known for reliability, but even the best equipment wears down over time if not properly maintained. Friction between moving parts—like the rack and pinion, rollers, and gearboxes—can cause stiffness, noise, and eventually, failure. That’s where lubrication comes in.

Think of it like this: your slide-out is like a drawer in a cabinet. If you never clean or oil the tracks, it starts to stick, squeak, or even jam. The same principle applies to your RV’s slide-out, just on a much larger and more complex scale. Without proper lubrication, you risk damaging expensive components, voiding warranties, or worse—getting stuck with a slide that won’t retract when you need to hit the road.

The Risks of Neglect

Ignoring lubrication might seem harmless at first. After all, the slide still moves, right? But over time, the lack of lubrication leads to increased friction, which generates heat and accelerates wear. Rollers can flatten or crack. Gears can strip. Seals can dry out and leak. And once a component fails, the repair cost can run into hundreds—or even thousands—of dollars.

Worse yet, a malfunctioning slide-out can become a safety hazard. Imagine trying to leave a campsite in a storm, only to find your bedroom slide won’t retract. Or worse, it starts moving on its own while driving. These aren’t just inconveniences—they’re real risks that proper maintenance can prevent.

Benefits of Regular Lubrication

On the flip side, a well-lubricated Lippert slide out operates smoothly, quietly, and reliably. You’ll notice the difference immediately: the slide extends and retracts with minimal effort, no jerking, and no strange noises. Plus, regular maintenance helps you spot potential problems early—like loose bolts, worn rollers, or misaligned tracks—before they turn into major repairs.

Beyond functionality, lubrication also protects your investment. RVs are expensive, and slide-out systems are among the most complex and costly parts to replace. By spending just 30 minutes every few months on lubrication, you can extend the life of your slide-out by years.

Understanding Your Lippert Slide Out System

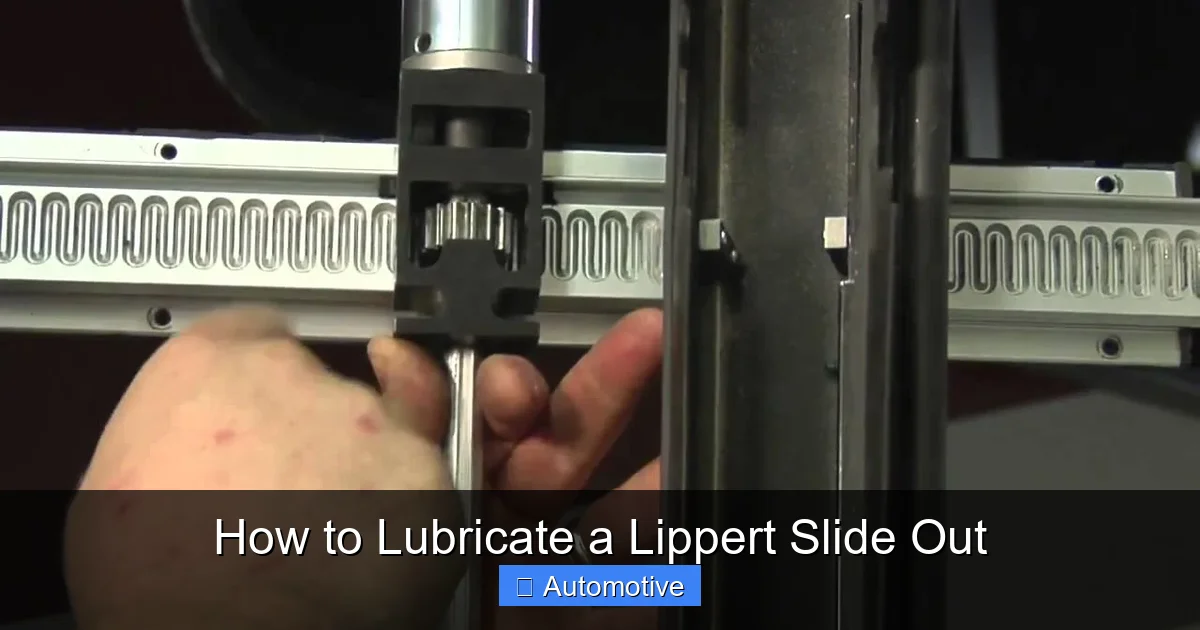

Visual guide about How to Lubricate a Lippert Slide Out

Image source: i.ytimg.com

Before you grab a grease gun and start spraying, it’s important to understand how your Lippert slide-out actually works. Not all slide-outs are the same, and knowing the mechanics helps you target the right areas for lubrication.

Lippert manufactures several types of slide-out systems, including electric rack-and-pinion, hydraulic, and cable-driven models. The most common in modern RVs is the electric rack-and-pinion system, which uses a motor to turn a gear (the pinion) that moves along a toothed bar (the rack) attached to the slide room.

Key Components That Need Lubrication

Here’s a breakdown of the main parts that benefit from regular lubrication:

– **Rack and Pinion Gear:** This is the heart of the system. The pinion gear engages with the rack to move the slide in and out. Over time, this area can collect dirt and lose lubrication, leading to grinding or skipping.

– **Roller Tracks and Rollers:** The slide room rides on a set of rollers that move along metal tracks. These rollers must spin freely to reduce friction. If they seize up, the motor has to work harder, which can lead to overheating or failure.

– **Gearbox and Motor Assembly:** The electric motor is connected to a gearbox that reduces speed and increases torque. While this area is usually sealed, some models have external gears or access points that may need occasional lubrication.

– **Pivot Points and Hinges:** On some slide-outs, especially larger or multi-section models, there are pivot points or hinges that allow the room to extend smoothly. These joints can dry out and cause binding.

– **Seals and Weatherstripping:** While not mechanical, the seals around the slide-out can dry out and crack if not treated with a silicone-based protectant. This leads to water leaks and air drafts.

Identifying Your Slide-Out Model

Lippert labels most of their components with model numbers, usually found on the motor housing, gearbox, or slide-out frame. Common models include the Lippert Ground Control 3.0, Slide-Out Motor SOA1712, and the newer Smart Jack systems. You can usually find this information in your RV owner’s manual or by looking for a metal tag near the motor.

Knowing your model helps you find the right maintenance instructions. For example, some systems have sealed gearboxes that don’t require user lubrication, while others have grease fittings (zerks) that need periodic greasing. Always refer to Lippert’s official documentation or contact their support team if you’re unsure.

Choosing the Right Lubricant for Your Slide Out

Visual guide about How to Lubricate a Lippert Slide Out

Image source: gocarlife.com

Not all lubricants are created equal—especially when it comes to RV slide-outs. Using the wrong product can do more harm than good. For example, petroleum-based greases can degrade rubber seals, while water-displacing sprays like WD-40 are great for loosening rust but aren’t designed for long-term lubrication.

Recommended Lubricant Types

For Lippert slide-outs, the best options are:

– **Silicone Spray:** Ideal for rollers, tracks, and seals. It’s water-resistant, won’t attract dirt, and won’t damage rubber or plastic components. Look for a high-quality RV-specific silicone spray like 3-IN-ONE RV Slide-Out Silicone Lubricant or Star Brite Slide-Out Silicone Lube.

– **PTFE-Based Dry Lubricant:** Products like DuPont Teflon Dry-Film Lubricant or LPS 2 provide long-lasting lubrication without attracting dust. Great for high-friction areas like the rack and pinion.

– **White Lithium Grease (in moderation):** While not ideal for all areas, a small amount of white lithium grease can be used on gear teeth or zerks if recommended by Lippert. Avoid over-application, as it can collect debris.

– **Rubber Protectant:** For seals and weatherstripping, use a silicone-based protectant like 303 Rubber Protectant or Gummi Pflege Stift. This keeps seals flexible and prevents cracking.

Lubricants to Avoid

– **WD-40:** It’s a solvent and water displacer, not a lubricant. It may help free a stuck part temporarily, but it evaporates quickly and offers no long-term protection.

– **Heavy Grease or Molybdenum Disulfide:** These can attract dirt and gum up over time, especially in dusty or wet environments.

– **Motor Oil or Cooking Oil:** These are not designed for mechanical systems and can degrade seals or wash away under pressure.

Application Tips

When applying lubricant, less is often more. Over-lubricating can cause buildup, attract dirt, and even interfere with sensors on newer Lippert systems. Use a spray nozzle or small brush to apply a thin, even coat. For hard-to-reach areas, consider using a flexible applicator tip or a spray can with an extension tube.

Always wipe away excess lubricant after application. This prevents dripping onto floors or carpets and reduces the chance of attracting dust.

Step-by-Step Guide to Lubricating Your Lippert Slide Out

Visual guide about How to Lubricate a Lippert Slide Out

Image source: shootingstar-rvresort.com

Now that you know why lubrication matters and what products to use, let’s walk through the actual process. This step-by-step guide will help you lubricate your Lippert slide out safely and effectively.

Step 1: Prepare Your RV

Before you begin, make sure your RV is parked on a level surface and the slide-out is fully retracted. Turn off the power to the slide-out system—either by switching off the breaker or disconnecting the battery. This prevents accidental activation while you’re working.

Gather your tools and supplies:

– Silicone spray or PTFE lubricant

– Clean rags or paper towels

– Soft-bristle brush (like an old toothbrush)

– Rubber protectant (for seals)

– Gloves (optional, but recommended)

Step 2: Clean the Slide-Out Components

Lubrication works best on clean surfaces. Use a dry rag to wipe down the rack and pinion, roller tracks, and visible gears. Remove any dirt, mud, or old grease. For stubborn grime, use a soft brush and a mild cleaner like dish soap and water—just make sure everything is dry before applying lubricant.

Pay special attention to the roller tracks. Dirt and debris can get packed into the grooves, causing the rollers to bind. A clean track ensures smooth movement.

Step 3: Lubricate the Rack and Pinion

Locate the rack (the long toothed bar) and the pinion gear (the small gear that engages with it). Spray a light coat of PTFE or silicone lubricant directly onto the teeth of both components. Move the slide out slightly (if safe to do so) to expose more of the rack, then lubricate the newly exposed section.

Avoid spraying directly into the motor or gearbox unless your manual specifies otherwise. Excess lubricant can attract dust or interfere with electrical components.

Step 4: Lubricate the Rollers and Tracks

Spray silicone lubricant along the entire length of the roller tracks. Then, manually rotate each roller to ensure the lubricant reaches the inner bearings. If a roller doesn’t spin freely, it may be worn or damaged and should be inspected further.

For rollers that are hard to reach, use a spray can with an extension tube or apply lubricant with a small brush.

Step 5: Treat the Seals and Weatherstripping

Spray a silicone-based rubber protectant onto the seals around the slide-out. Focus on areas that look dry, cracked, or brittle. This helps maintain a tight seal and prevents water intrusion.

Avoid using petroleum-based products on seals, as they can cause swelling or deterioration over time.

Step 6: Operate the Slide-Out

Once everything is lubricated, restore power and slowly extend and retract the slide-out several times. This helps distribute the lubricant evenly and ensures smooth operation.

Listen for unusual noises—grinding, squeaking, or jerking—which could indicate a problem. If the slide moves smoothly and quietly, you’re good to go.

Step 7: Wipe Away Excess

After operating the slide, wipe away any excess lubricant from visible surfaces. This keeps your RV clean and prevents dripping onto floors or carpets.

Maintenance Schedule and Best Practices

Lubricating your Lippert slide out isn’t a one-time task—it’s part of an ongoing maintenance routine. How often you need to lubricate depends on usage, climate, and environmental conditions.

Recommended Lubrication Frequency

– **Every 3–6 months:** For RVers who use their RV regularly, lubricate the slide-out every 3 to 6 months.

– **After heavy use or travel:** If you’ve been on a long trip or used the slide-out frequently, give it a quick lube job before storing.

– **Before winter storage:** Cold weather can cause seals to dry out and lubricants to thicken. A fresh application before winter helps protect your system.

– **After exposure to water or dirt:** If your RV has been in rain, mud, or dusty conditions, clean and lubricate the slide-out as soon as possible.

Seasonal Maintenance Tips

– **Spring:** Inspect for winter damage, clean debris, and apply fresh lubricant.

– **Summer:** Check for overheating or excessive wear due to frequent use.

– **Fall:** Prepare for storage—lubricate, clean, and cover if necessary.

– **Winter:** If storing outdoors, consider using a slide-out cover to protect against snow and ice.

Inspection Checklist

During each lubrication session, take a few minutes to inspect your slide-out for signs of wear or damage:

– Are the rollers spinning freely?

– Are there cracks or flat spots on the rollers?

– Is the rack bent or missing teeth?

– Are the bolts and fasteners tight?

– Are the seals intact and flexible?

– Is there any sign of water leakage?

Catching small issues early can prevent major repairs down the road.

Troubleshooting Common Slide-Out Problems

Even with regular maintenance, slide-outs can develop issues. Here’s how to identify and address common problems related to lubrication.

Slide-Out Won’t Move or Moves Slowly

This is often caused by lack of lubrication, dirty tracks, or worn rollers. Start by cleaning and lubricating the system. If the problem persists, check the motor, fuses, and wiring.

Grinding or Squeaking Noises

These sounds usually indicate metal-on-metal contact due to insufficient lubrication. Inspect the rack and pinion, and apply PTFE or silicone lubricant. If the noise continues, the gear may be damaged and need replacement.

Slide-Out Binds or Jerks

Binding can be caused by misaligned tracks, dirty rollers, or dried-out seals. Clean and lubricate all moving parts. If the issue remains, have a professional check the alignment.

Leaks Around the Slide-Out

Dry or cracked seals are a common cause. Apply rubber protectant and monitor for improvement. If leaks persist, the seals may need replacement.

Conclusion

Lubricating your Lippert slide out is one of the simplest yet most effective ways to keep your RV running smoothly. It takes just a little time and the right products, but the payoff is huge: quieter operation, fewer repairs, and peace of mind on the road.

By following this guide—choosing the right lubricant, targeting the correct components, and sticking to a regular maintenance schedule—you’ll extend the life of your slide-out system and enjoy more trouble-free adventures. Remember, a well-maintained RV is a happy RV. So grab your silicone spray, roll up your sleeves, and give your slide-out the care it deserves.

Frequently Asked Questions

How often should I lubricate my Lippert slide out?

Most RVers should lubricate their Lippert slide out every 3 to 6 months, or after heavy use. If you travel frequently or expose your RV to dirt, dust, or moisture, consider lubricating more often.

Can I use WD-40 to lubricate my slide out?

WD-40 is not recommended for long-term lubrication. It’s a water displacer and solvent, not a true lubricant. Use silicone spray or PTFE-based products instead for lasting protection.

What type of lubricant is best for Lippert slide outs?

Silicone spray and PTFE-based dry lubricants are ideal. They resist water, don’t attract dirt, and won’t damage rubber seals. Avoid petroleum-based greases unless specified by Lippert.

Do I need to lubricate the motor or gearbox?

Most Lippert motors and gearboxes are sealed and don’t require user lubrication. Check your owner’s manual—only lubricate external gears or zerks if instructed.

Why is my slide out making noise?

Noises like grinding or squeaking usually mean insufficient lubrication or worn components. Clean and lubricate the rack, pinion, and rollers. If noise persists, inspect for damage.

Can I lubricate my slide out in cold weather?

Yes, but use a lubricant formulated for low temperatures. Avoid thick greases that can harden in the cold. Silicone sprays work well in winter conditions.