A Deep Dive into Types of Lithium Lon Batteries Used in Electric Vehicles

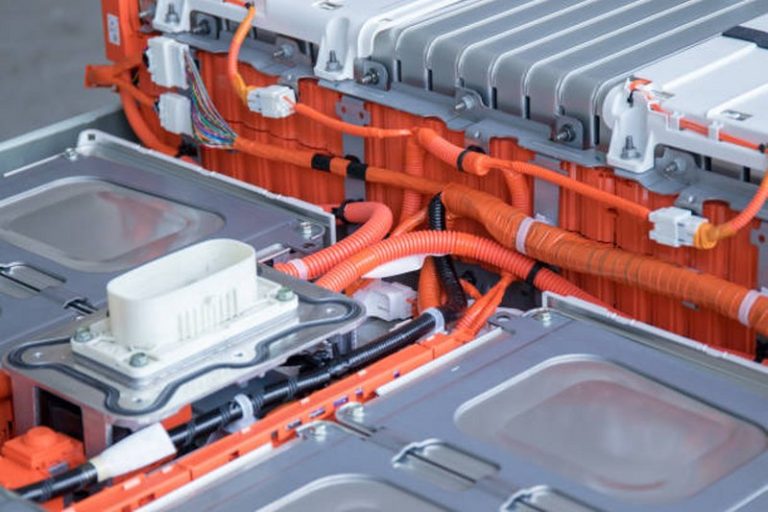

A Deep Dive into Lithium-Ion Batteries for Electric Vehicles

Lithium-ion batteries have changed the electric vehicle (EV) industry. They store the energy that powers these green vehicles. But not all manufacturers create lithium-ion batteries equally. Types of lithium ion batteries used in electric vehicleshave unique traits. Each has pros and cons. This article will explore the types of lithium-ion batteries in EVs. It will cover their chemistries, performance, and uses.

Understanding Lithium-Ion Batteries:

Before we dive into the types, we must grasp the basics of lithium-ion batteries. This includes their parts and how they work. These batteries consist of a cathode, anode, electrolyte, and separator. During discharge, lithium ions move from the anode to the cathode. This generates an electric current. The reverse occurs during charging.

Key Factors to Consider:

Several factors influence the performance of lithium-ion batteries in EVs:

- Energy density: This measures the amount of energy stored per unit mass or volume. A higher energy density translates to a longer driving range.

- Power density: This refers to the rate at which the battery can deliver energy. A higher power density enables faster acceleration and peak performance.

- Cycle life: The number of charge-discharge cycles a battery can endure before it wears out.

- Safety: The battery’s ability to avoid failure under abuse, such as overcharging or overheating.

- Cost: The price of the battery materials and manufacturing processes.

Types of Lithium-Ion Batteries:

- Lithium-Cobalt Oxide (LCO)

- Pros: High energy density, fast charging, and good power output.

- Cons: Relatively short cycle life, prone to thermal runaway, and can be expensive.

- Applications: They are mainly in consumer electronics, like smartphones and laptops. Some early EVs used LCO batteries.

- Lithium Nickel Manganese Cobalt Oxide (NMC)

- Pros: Offers a balance between energy density, power density, and cycle life. Can be customized with different nickel, manganese, and cobalt ratios to optimize performance.

- Cons: Can be susceptible to thermal runaway if not managed properly.

- Applications: Common in modern EVs, especially those for long-range and fast charging.

- Lithium Iron Phosphate (LFP)

- Pros: Excellent thermal stability, long cycle life, and a good safety record.

- Cons: Lower energy density compared to NMC, which can limit the driving range.

- Applications: EVs are using them more for their safety and fast charging.

- Lithium Nickel Cobalt Aluminum Oxide (NCA)

- Pros: High energy density, like LCO, but with improved safety and cycle life.

- Cons: Can be more expensive to produce.

- Applications: Used in some high-performance EVs, especially those that focus on range.

- Lithium Titanite Oxide (LTO)

- Pros: Extremely fast charging capabilities, excellent safety, and long cycle life.

- Cons: Lower energy density, which limits the driving range.

- Applications are primarily used in situations where rapid charging is crucial. Examples include public transport and grid energy storage.

Future Trends and Innovations:

Researchers and manufacturers are testing new materials for lithium-ion batteries. They want to boost performance and cut costs. Some promising developments include:

- Solid-state batteries use solid, not liquid, electrolytes. This could improve safety, energy density, and cycle life.

- Silicon-based anodes: Silicon has a higher capacity than graphite ones. But its volume expands during cycling, which must be fixed.

- Battery management systems (BMS): Advanced BMS can optimize battery performance. They can also enhance safety and extend battery life.

As demand for electric vehicles grows, advanced lithium-ion batteries are key. They will help boost adoption and solve energy storage issues. Studying the types of lithium-ion batteries can help us. They have unique traits. This knowledge can inform us about the future of electric mobility.