Electric Vehicle Battery Manufacturing Waste

Fully electric vehicle. A type of electric vehicle that has a rechargeable battery. Rechargeable batteries use stored chemical energy. Which has no second source. Electric vehicle battery manufacturing waste bad for the environment.

Propulsion is a hydrogen fuel cell. Internal combustion engine. Internal combustion engine for propulsion. Instead, it uses electric motors and motor controllers. They draw all their power from the battery pack. No fuel cell or fuel tank. This includes, but is not limited to, Motorcycle, bicycles. There are scooters and skateboards. Rail cars and bus-truck vehicles.

Electric vehicle battery manufacturing waste Most Important. Produce no greenhouse gas emissions. But they can do so in the production of electricity used to power them. Two factors drive battery-electric vehicle emissions.

One is the carbon intensity of the Electric vehicle battery recycling. Usually expressed in grams of CO2 per kWh, Another is the specific vehicle cost per kilometer or kWh.

Which vehicles are powered by batteries only?

Battery electric vehicles are also known as plug-in or pure EVs. Using an electric motor. Runs on battery power only. Which means they produce zero emissions from driving. There is a standard power outlet for recharging. Or use public charging stations.

It is important to recycle Electric vehicle battery manufacturing waste right place. Battery storage is global energy. A key element for global energy change.Currently more dependent on electricity storage. The availability of energy is the most important factor for the vitality of the economy. Batteries make the most sense for mobile storage infrastructure.

This can be seen as one of the most meaningful infrastructure projects. Which is based on renewable energy. A fully sustainable economy facilitates energy transitions. A meta-study graphically demonstrates the importance of electricity storage. Illustrates technology in context.

Is EV battery manufacturing bad for the environment?

Waste management takes the form of a funnel. On top of that, it is the most desirable method for the environment. Electric vehicle battery manufacturing waste?

And below is the minimum desired:.

For lithium-ion batteries. You want to start at the top. I want to maximize my effort there. You want to work your way down as slowly as possible.

5 Best Battery Electric Cars 2024

-

Cupra Born:

Autocar’s best-handling. The most fun electric car ever. Conducted an annual test of sales for several years. Like the MG 4 XPower and the Abarth 500e. Currently champion Cupra Bourne. The Born size and usability. Weight and strength. The real world sits at a compelling nexus of range and value. It doesn’t seem too much to compromise efficiency when motoring fast. It has an attractively balanced rear-wheel-drive chassis.

There is some precision to control the body. It also has four usable seats and a decent boot. The Capra Bourne will cover 220 real-world miles. Enough to come and go from preferred roads. There’s also the personality and attitude to make the trip worthwhile.

-

Hyundai Ioniq 5 N:

Ioniq 5N brand electric crossover. Sends electric sports cars into territory. Using a dual-motor setup. The Ioniq 5N produces 641 bhp and 549 lb ft. That hits 0-62 mph in a surprisingly quick 3.4 seconds. Hyundai claims 278 miles on a single charge for the 89 kWh battery.

It is heavier than a traditional sports car. It may seem too big. You can think of the words as the same. It has a built-in sound generator. So that drivers can select different ‘engine’ notes. Works together with synthetic gear shift. Gap between piston force and electric. More reliable than other high-performance EVs. Landmark is a real driver’s car.

-

Volkswagen ID 7:

The Volkswagen ID 7 is the German firm’s first electric saloon. Which also comes as an estate. There are many things about it. A good choice for drivers who drive long distances. ID 7 is a single motor. It comes as standard with the setup. Produces 282 bhp and 402 lb ft. Long-range cars are equipped with an 86 kWh battery. Provides a range exceeding 400 miles.

The maximum charging speed is 200 kW. The ID7 drives superbly for such a big and heavy car. This is a Tesla Model 3. Not as sporty as the BMW i4. But ID 7 is very round. It feels agile. Gives enough punch and grips well. ID 7 for space: 532 liters of boot space. And has a limp-like backspace. It is truly best in class in this regard. The whole family will feel comfortable.

-

Porsche Taycan:

Porsche is truly a luxury car. While the rest of the industry stole a march. It then launched the Taycan electric saloon. The first Taycan arrived in 2019. This is his management application during that period. A fantastic vehicle for driver engagement and DC fast-charging speed. A new Taycan has arrived. Which is a better range? All set to bring many updates with performance and efficiency.

The Tycan isn’t the lightest EV. The 92-kWh lithium-ion drive battery itself weighs 650 kg. The Porsche effectively levels the battery under the floor. Holes were cut out of it to enable the driver to sit down in the car. So innovated by lowering the entire profile of the car. Provides a sensational driving position. A lower center of gravity. The car’s tactile handling starts perfect.

-

Rolls-Royce Spectre:

The Rolls-Royce Specter has impressed everyone in the UK, South Africa, and North America.

Especially praised for its ride isolation and cushioned body control. Even its massive 23-inch alloy wheels. The unusual smoothness of its ‘one-pedal’ driving. It’s unexpectedly responsive in steering and handling.

Advantages of Electric vehicle battery manufacturing waste:

- I paid $0.10 per kilowatt.

- Cars can run on gasoline. Battery electric vehicles costs less than $1 a gallon.

- They are environment friendly. Because they do not emit pollutants.

- Car drivers reduced CO2 emissions by more than 177,758,804 kg.

- Low maintenance of an efficient electric motor. Electric motors have fewer parts.

- Which leads to less damage than a traditional non-electric vehicle. Which means saving on operating costs!

Which is better, BEV or FCEV?

Both FCEVs and BEVs offer zero-emission transportation solutions. BEVs have a more simple energy conversion process. Exhibits high wheel-to-wheel efficiency due to renewable power generation potential.

Usually, lithium-ion batteries. Which has a high strength-to-weight ratio. Designed for energy density. Most battery-electric vehicle technologies have much lower specific energy than liquid fuels. This increases the weight of the vehicle. Or by reducing their range.

Lithium uses nickel, manganese, and cobalt oxide. Li-NMC batteries are the most common in EVs. Lithium-iron phosphate batteries are on the rise. BEVs will reach 41% of the global market share for power in 2023. Commercial passenger cars used sodium-ion batteries. Which completely bypasses the need for vital minerals.

Conclusion:

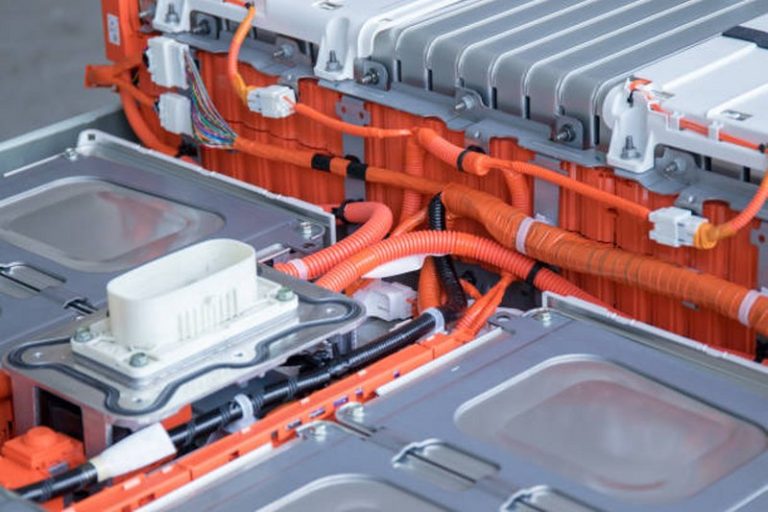

There are mainly three stages in the production of Battery electric vehicles. Materials production, cell production, and integration. EV battery manufacturing process. It is painted in gray, green and orange colors respectively. Here the process is called cell hardware.

The casing and current collector are not included. During the material manufacturing process. The active ingredient conductivity additive, polymer binder, and solvent are mixed first.

The current collector is ready for the drying process. Methods for preparing active materials depend on electrode chemistry. Electric vehicle battery manufacturing waste Should Recycle properly.

Cathodes use mostly transition metal oxides. Such as lithium, nickel, manganese, and cobalt oxide. Otherwise, lithium metal phosphates. Lithium-iron phosphates.