Difference Between Disc Brake and Drum Brake

The core difference between disc brakes and drum brakes lies in their design and how they apply stopping force. Disc brakes use a rotor and caliper system for superior, consistent stopping power, while drum brakes use a drum and shoes, often found on older or rear axles for simpler, less demanding braking.

Key Takeaways

- Understand disc and drum brake designs simply.

- Compare their performance and efficiency with ease.

- Learn where each brake type is typically used.

- Discover common issues and maintenance tips.

- Gain confidence in your car’s braking system knowledge.

When you press the brake pedal in your car, you’re engaging a critical system that keeps you safe on the road. But have you ever wondered if all cars use the same kind of brakes? You might have heard terms like “disc brakes” and “drum brakes,” and perhaps they sound a bit technical. Understanding the difference between disc brake and drum brake systems is essential for any car owner. It helps you appreciate your vehicle’s engineering and know what to expect regarding performance and maintenance. Don’t worry if it seems confusing; we’re here to break it down into simple terms. Let’s dive into what makes these two common braking systems tick and how they impact your driving experience.

What Are Brakes and Why Are They Important?

At its heart, a car’s braking system is designed to convert the kinetic energy of your moving vehicle into heat energy, thereby slowing down or stopping it. When you step on the brake pedal, you activate a hydraulic system that pushes brake pads or shoes against a spinning component attached to your wheel. This friction is what slows your car. Regular maintenance and understanding how your brakes work are vital for safe driving. The National Highway Traffic Safety Administration (NHTSA) offers resources on vehicle safety that highlight the importance of a well-maintained braking system for preventing accidents.

Understanding Disc Brakes: The Modern Standard

Disc brakes are the more common and advanced braking system found on most modern vehicles, especially on the front wheels where the majority of the stopping force is needed. They offer superior performance, especially in demanding conditions. Let’s explore how they work and their advantages.

How Disc Brakes Work

A disc brake system consists of a few key components:

- Rotor: This is a flat, circular metal disc that rotates with the wheel. It’s essentially the surface that the braking components press against.

- Caliper: This is a clamp-like device that houses the brake pads. It is mounted over the rotor. When you brake, hydraulic pressure pushes pistons within the caliper, forcing the brake pads to squeeze the rotor.

- Brake Pads: These are friction materials mounted inside the caliper. They are the parts that make direct contact with the rotor to create friction and slow the vehicle.

- Brake Fluid: This hydraulic fluid transmits the force from your brake pedal to the caliper pistons.

When you press the brake pedal, hydraulic pressure forces the brake pads to clamp down on the spinning rotor. This friction creates heat and slows the wheel’s rotation.

Advantages of Disc Brakes

Disc brakes have several benefits that make them the preferred choice for most vehicles:

- Superior Stopping Power: They provide more consistent and powerful braking, especially during hard stops.

- Better Heat Dissipation: The open design of disc brakes allows air to circulate around the rotor, which helps to dissipate heat more effectively. This reduces the risk of brake fade (a loss of braking effectiveness due to overheating).

- Consistent Performance in Wet Conditions: The rotor and pads tend to shed water more easily than drum brakes, leading to more reliable braking in rain.

- Easier Maintenance and Inspection: It’s generally simpler to inspect and replace brake pads on a disc brake system.

Disadvantages of Disc Brakes

While excellent, disc brakes aren’t without their minor drawbacks:

- Higher Cost: They are typically more expensive to manufacture than drum brakes.

- More Susceptible to Road Grime: The open design can allow more dirt and debris to get onto the rotor and pads, potentially causing wear.

- Can Be Noisier: Sometimes, disc brake pads can produce squealing or grinding noises.

Understanding Drum Brakes: The Traditional System

Drum brakes represent an older, more traditional braking technology. While less common as the primary braking system on new cars, they are still found on the rear axles of many vehicles, and as the sole braking system on some lighter vehicles and older models. They are known for their simplicity and cost-effectiveness.

How Drum Brakes Work

A drum brake system also consists of several components, but they are arranged differently:

- Brake Drum: This is a hollow, cylindrical component that rotates with the wheel. It’s shaped like a drum, hence the name.

- Brake Shoes: These are curved pieces with a friction lining. They are positioned inside the brake drum.

- Wheel Cylinder: This is a hydraulic cylinder that contains pistons. When you brake, hydraulic pressure pushes these pistons outward.

- Return Springs: These springs pull the brake shoes back to their resting position when you release the brake pedal.

When you press the brake pedal, hydraulic fluid pushes pistons in the wheel cylinder outward. These pistons force the brake shoes outward, pressing their friction material against the inner surface of the rotating brake drum. This friction slows the wheel.

Advantages of Drum Brakes

Drum brakes have some advantages that have kept them in use:

- Lower Cost: They are generally less expensive to produce than disc brakes.

- Parking Brake Integration: Many drum brake systems are easily integrated with a parking brake mechanism.

- Self-Energizing Effect: In some designs, the rotation of the drum can help to wedge the brake shoes more firmly, providing increased braking force without additional pedal pressure.

- Protection from Debris: The enclosed nature of the drum can offer some protection from dirt and road grime.

Disadvantages of Drum Brakes

However, drum brakes also have significant drawbacks compared to disc brakes:

- Poorer Heat Dissipation: The enclosed design traps heat, making them more prone to brake fade, especially during heavy or prolonged braking.

- Less Consistent Performance in Wet Conditions: Water can get trapped inside the drum, significantly reducing braking effectiveness until it evaporates.

- More Complex Maintenance: Replacing brake shoes and drums can be more labor-intensive and require more specialized tools.

- Lower Stopping Power: They generally offer less stopping power and responsiveness than disc brakes.

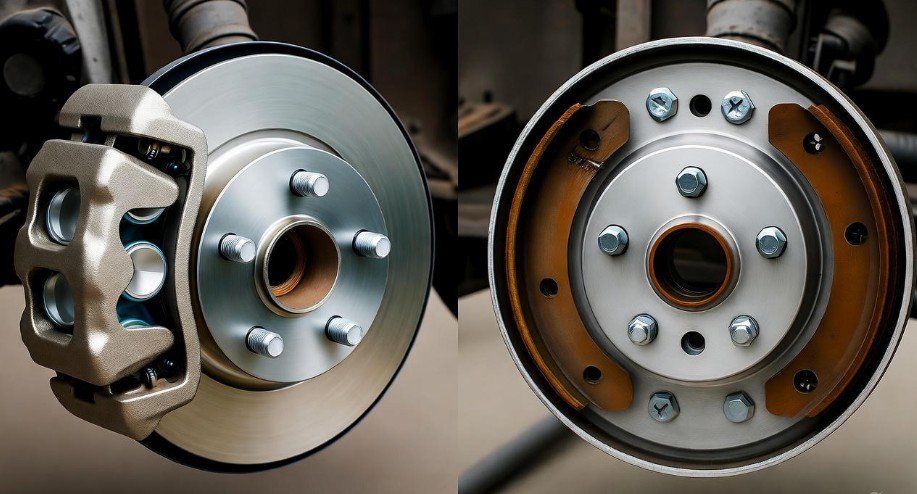

Visualizing the Difference: Disc vs. Drum

To quickly grasp the difference between disc brake and drum brake systems, consider this visual comparison. Imagine a bicycle with a caliper squeezing a rim versus a roller skate with a wheel inside a housing. While not perfect analogies, they help illustrate the core mechanical difference.

Table: Disc Brake vs. Drum Brake Comparison

| Feature | Disc Brakes | Drum Brakes |

|---|---|---|

| Primary Components | Rotor, Caliper, Brake Pads | Brake Drum, Brake Shoes, Wheel Cylinder |

| Operation | Pads squeeze a rotating disc (rotor) | Shoes press against the inside of a rotating drum |

| Stopping Power | Higher, more consistent | Lower, can be less consistent |

| Heat Dissipation | Excellent (open design) | Poor (enclosed design) |

| Wet Performance | Better (sheds water easily) | Worse (water trapped inside) |

| Maintenance Complexity | Generally easier | More complex |

| Cost | Higher | Lower |

| Common Location | Front wheels of most cars; all wheels on performance vehicles | Rear wheels of many cars; older vehicles; some light trucks |

Why Your Car Might Have Different Brakes on Front and Rear

You’ve probably noticed that many cars have disc brakes on the front wheels and either disc or drum brakes on the rear. This is a deliberate design choice based on physics and how braking works. Approximately 70-80% of a vehicle’s braking force is generated by the front wheels due to weight transfer. When you brake, the car’s momentum shifts forward, pressing down on the front tires. Therefore, equipping the front with the more powerful and efficient disc brakes makes the most sense for optimal stopping performance. Rear brakes assist in slowing the vehicle and are crucial for stability, but they don’t bear as much of the initial stopping load.

When to Be Concerned: Common Brake Issues

Regardless of whether you have disc or drum brakes, they require regular checks. Recognizing the signs of potential problems can prevent serious safety issues and costly repairs. Here are some common brake issues to watch out for:

- Squealing or Grinding Noises: This is often the first sign that your brake pads are worn down and need replacement. Grinding noises can indicate metal-on-metal contact, which can damage the rotors.

- Spongy or Soft Brake Pedal: If your brake pedal feels soft or goes down further than usual, it could indicate air in the brake lines or a leak in the hydraulic system.

- Vibration or Pulsation: When you brake, if you feel a pulsing sensation in the brake pedal or steering wheel, it often means the brake rotors are warped or uneven.

- Vehicle Pulling to One Side: If your car pulls to the left or right when you brake, it could indicate a problem with a brake caliper, a blocked brake line, or uneven wear on one side.

- Burning Smell: An unusual burning smell while driving, especially after braking, might suggest that the brakes are overheating.

If you experience any of these symptoms, it’s crucial to have your brakes inspected by a qualified mechanic immediately. For more detailed information on vehicle maintenance and safety, resources like the U.S. Department of Transportation’s Federal Motor Carrier Safety Administration (FMCSA) website provide insights into vehicle safety standards.

Maintenance Tips for Your Braking System

Proper maintenance is key to ensuring your brakes last longer and perform reliably. Here are some tips for both disc and drum brake systems:

- Regular Inspections: Have your brakes inspected by a professional at least once a year, or more frequently if you drive in harsh conditions or notice any issues.

- Check Brake Fluid: Ensure your brake fluid is at the correct level and change it according to your vehicle manufacturer’s recommendations. Old brake fluid can absorb moisture, reducing its effectiveness.

- Replace Worn Pads/Shoes: Don’t wait until they are completely worn out. Replacing brake pads or shoes at the recommended interval prevents damage to rotors or drums.

- Inspect Rotors/Drums: While inspecting pads or shoes, professionals should also check rotors and drums for wear, damage, or warping.

- Cleanliness: While you can’t easily clean drum brakes, you can help keep disc brake components cleaner by washing your car regularly, paying attention to the wheels.

Following these steps can help you maintain the integrity of your braking system.

Pro Tips:

Bedding-in new brake pads: After replacing brake pads, it’s important to “bed them in” to ensure optimal performance. This usually involves a series of moderate to firm stops from different speeds, followed by cooling periods, without coming to a complete stop. Consult your mechanic or the pad manufacturer’s instructions for the specific procedure for your vehicle.

Understanding Brake Rotors vs. Brake Drums

The primary friction surfaces in disc and drum brake systems are the rotor and the drum, respectively. They serve a similar purpose of providing a surface for friction but operate quite differently.

Brake Rotors: The Disc’s Surface

Brake rotors are typically made of cast iron or sometimes more advanced materials like carbon-ceramic for high-performance vehicles. They are exposed to the elements, which helps with cooling but also makes them susceptible to rust and damage from debris. Rotors can become grooved, warped, or cracked over time, requiring resurfacing or replacement.

Brake Drums: The Enclosed System

Brake drums are usually made of cast iron and are enclosed. This enclosure protects the brake shoes and the inner surface of the drum from direct exposure to dirt and moisture. However, it also traps heat and can accumulate brake dust, which can harden and affect performance. Drums can wear unevenly or become distorted, also necessitating resurfacing or replacement.

Choosing the Right Brake System for Your Needs

For the average car owner in the USA, understanding the difference between disc brake and drum brake systems is more about appreciating your car’s existing technology. Most new vehicles are equipped with disc brakes on all four wheels or at least on the front for optimal safety and performance. If you’re looking at purchasing a vehicle, especially a performance-oriented one, you’ll likely find disc brakes all around. For a standard sedan or SUV, disc front/drum rear is a common and effective setup. If you’re an expat or new to driving in the U.S., knowing that disc brakes are generally considered superior for stopping power and heat management is a good takeaway.

Frequently Asked Questions (FAQ)

What is the main difference between disc and drum brakes?

The main difference is how they create friction. Disc brakes use pads that squeeze a rotor, while drum brakes use shoes that press against the inside of a drum.

Are disc brakes better than drum brakes?

For most modern vehicles and driving conditions, disc brakes are generally considered better due to superior stopping power, better heat dissipation, and more consistent performance, especially in wet weather.

Why do some cars have drum brakes on the rear?

Drum brakes are less expensive to manufacture and can be easily integrated with a parking brake. Since the front wheels handle most of the braking force, a drum brake setup on the rear can be sufficient for many vehicles.

Can I convert my drum brakes to disc brakes?

Yes, it is possible to convert drum brakes to disc brakes, often through aftermarket kits. However, this can be a complex and expensive modification that should be performed by a professional mechanic.

How often should I check my brake pads and rotors/drums?

It’s recommended to have your brakes inspected by a professional at least once a year or every 12,000 miles. Your mechanic can advise on specific intervals based on your driving habits and vehicle.

What does it mean if my brake pedal feels spongy?

A spongy brake pedal often indicates air in the brake lines or a leak in the hydraulic system. This is a serious issue and requires immediate attention from a mechanic.

How does the parking brake work with disc vs. drum brakes?

Parking brakes can be integrated differently. On drum brakes, they often use a lever that forces the shoes against the drum. On disc brakes, some systems use a small drum mechanism integrated within the rear caliper, while others use a cable that actuates a lever on the caliper itself.

Conclusion

Understanding the difference between disc brake and drum brake systems demystifies a crucial part of your vehicle’s safety. While disc brakes offer enhanced performance and are the standard for modern automotive engineering, drum brakes still serve a purpose, particularly on rear axles due to cost-effectiveness and ease of parking brake integration. Both systems, however, rely on friction to bring your car to a safe stop. Regular inspection and maintenance are paramount for any braking system, ensuring you and your passengers remain safe on the diverse roads of America. By staying informed, you can drive with greater confidence and peace of mind.