How to Install Trailer Bearings

Installing trailer bearings correctly is essential for safe towing and long-lasting performance. This guide walks you through every step—from inspection to reassembly—so you can do it confidently at home with basic tools.

In This Article

- 1 Key Takeaways

- 2 📑 Table of Contents

- 3 Why Trailer Bearing Maintenance Matters

- 4 Tools and Materials You’ll Need

- 5 Step-by-Step Guide to Removing Old Bearings

- 6 How to Install New Trailer Bearings

- 7 Reassembling and Final Checks

- 8 Tips for Long-Term Bearing Health

- 9 Common Mistakes to Avoid

- 10 Conclusion

- 11 Frequently Asked Questions

- 11.1 How often should I replace trailer bearings?

- 11.2 Can I reuse old bearings if they look okay?

- 11.3 What type of grease should I use for trailer bearings?

- 11.4 How tight should the spindle nut be?

- 11.5 Why is my trailer wheel wobbling after installation?

- 11.6 Do I need special tools to install trailer bearings?

Key Takeaways

- Inspect before installing: Always check wheel hubs, races, and bearings for wear or damage before starting the installation.

- Use the right tools: A bearing packer, socket set, torque wrench, and cotter pins are essential for a proper job.

- Pack bearings with grease: Properly greasing bearings prevents overheating and extends their lifespan.

- Follow torque specs: Over-tightening or under-tightening the spindle nut can cause bearing failure or wheel wobble.

- Install new seals: Always replace oil seals to prevent grease leakage and water contamination.

- Test after installation: Spin the wheel and check for smooth rotation and proper alignment before hitting the road.

- Maintain regularly: Re-pack bearings every 12,000 miles or annually to avoid costly repairs.

📑 Table of Contents

Why Trailer Bearing Maintenance Matters

If you tow a trailer—whether it’s for work, camping, or hauling equipment—you know how important it is to keep everything running smoothly. One of the most critical yet often overlooked components is the trailer wheel bearing. These small but mighty parts allow your trailer wheels to spin freely, reducing friction and heat buildup. When they fail, the results can be dangerous: wheel lockup, tire blowouts, or even complete wheel separation on the highway.

Many trailer owners don’t realize that bearings need regular maintenance. Unlike car wheel bearings, which are often sealed for life, most trailer bearings require periodic inspection, cleaning, repacking, and replacement. Ignoring them can lead to expensive repairs or, worse, accidents. The good news? Installing trailer bearings isn’t as hard as it sounds—especially if you follow a clear, step-by-step process.

In this guide, we’ll walk you through how to install trailer bearings like a pro. Whether you’re a weekend warrior or a full-time hauler, you’ll learn what tools you need, how to inspect your components, and how to get your trailer back on the road safely. No fancy shop required—just basic tools, a little patience, and this guide.

Tools and Materials You’ll Need

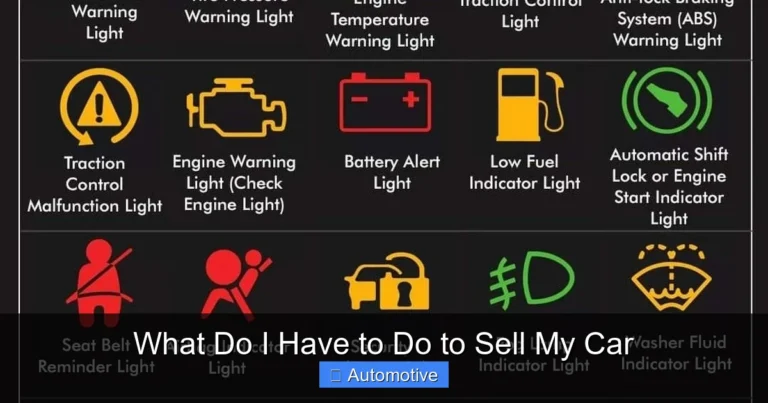

Visual guide about How to Install Trailer Bearings

Image source: i.ytimg.com

Before you start, gather all the tools and supplies. Having everything ready will save time and prevent frustration mid-job. Here’s what you’ll need:

Essential Tools

- Jack and jack stands: To safely lift and support the trailer.

- Lug wrench or impact wrench: For removing lug nuts.

- Socket set: Typically includes 1/2″, 9/16″, and 3/4″ sockets for spindle nuts and bolts.

- Torque wrench: Critical for tightening spindle nuts to the correct specification.

- Bearing packer (optional but helpful): Makes greasing bearings faster and cleaner.

- Grease gun: For applying fresh marine-grade or high-temperature grease.

- Pliers and screwdrivers: For removing cotter pins and seals.

- Rubber mallet: Helps gently tap components into place.

- Clean rags and brake cleaner: For cleaning parts and removing old grease.

- Work gloves and safety glasses: Protect your hands and eyes from grease and debris.

Replacement Parts

- New bearings (inner and outer): Match the size and type to your trailer hub (common sizes include 1-3/8″ and 1-1/4″).

- New races (if needed): These sit inside the hub and support the bearings. Replace if pitted or worn.

- New oil seals: Always install new seals—never reuse old ones.

- Cotter pins: Use new ones each time to ensure proper locking.

- High-temperature grease: Marine-grade or lithium-based grease rated for high heat and moisture resistance.

Optional but Helpful

- Bearing buddy or dust cap with grease zerk: Allows you to add grease without removing the hub.

- Hub puller (for stubborn hubs): Helps remove hubs that are stuck due to corrosion.

- Digital caliper: For measuring bearing and race dimensions accurately.

Having the right tools not only makes the job easier but also ensures a safer, more reliable installation. Don’t skip the torque wrench—this is one tool you can’t afford to guess with.

Step-by-Step Guide to Removing Old Bearings

Visual guide about How to Install Trailer Bearings

Image source: i.ytimg.com

Now that you’re prepared, let’s get started. The first phase is removing the old bearings and inspecting the components. Take your time—rushing can lead to mistakes or damage.

Lift and Secure the Trailer

Start by parking your trailer on a flat, level surface. Engage the parking brake and chock the wheels that will remain on the ground. Use a jack to lift the side of the trailer you’re working on, then place jack stands under the frame for safety. Never rely solely on the jack—always use stands.

Once the trailer is secure, remove the wheel. Use a lug wrench or impact wrench to loosen the lug nuts while the wheel is still on the ground, then finish removing them after lifting. Set the wheel aside in a clean area.

Remove the Hub Assembly

Next, locate the dust cap on the center of the hub. Use a screwdriver or pry bar to gently pop it off. Underneath, you’ll see the spindle nut and washer. Use pliers to remove the cotter pin, then unscrew the spindle nut. Some trailers use a castle nut with a cotter pin; others may have a split pin or lock washer.

Once the nut is off, carefully pull the hub assembly straight off the spindle. It may be tight due to rust or old grease. If it doesn’t come off easily, tap it gently with a rubber mallet. Avoid using a metal hammer, which can damage the hub.

Extract the Old Bearings and Seals

With the hub removed, you’ll see the inner and outer bearings seated inside. Use a screwdriver or seal puller to remove the oil seal from the back of the hub. Be careful not to scratch the seal bore.

Next, remove the outer bearing. It should slide out easily. The inner bearing is trapped behind the seal, so you’ll need to push it out from the back. You can use a bearing puller or a long drift punch and hammer to tap it out gently.

Once both bearings are out, inspect the races—the metal rings pressed into the hub. If they’re pitted, cracked, or worn, they need to be replaced. Use a race puller or a drift punch to remove old races. Clean the hub thoroughly with brake cleaner and a rag.

Inspect All Components

This is a crucial step. Look closely at the spindle, hub, bearings, and races. Check for:

- Scoring or pitting on the spindle

- Cracks or wear in the hub

- Flat spots or discoloration on bearings

- Rust or corrosion inside the hub

If any part shows significant wear, replace it. It’s better to spend a little extra now than risk a failure on the road.

How to Install New Trailer Bearings

Visual guide about How to Install Trailer Bearings

Image source: assets.website-files.com

With the old parts removed and everything cleaned, it’s time to install the new bearings. This is where precision matters.

Install New Races (If Needed)

If you’re replacing the races, press them into the hub using a race installer tool or a socket that fits the outer edge. Tap gently with a hammer until they’re fully seated. Make sure they’re flush and level—misaligned races can cause premature wear.

Pack the Bearings with Grease

Proper greasing is essential. You can do this by hand or with a bearing packer. Here’s the hand method:

- Scoop a generous amount of grease into your palm.

- Press the bearing into the grease, working it into the rollers.

- Rotate the bearing and continue pressing until grease oozes out the other side.

- Fill the cavity between the rollers completely.

A bearing packer makes this faster and cleaner. Simply place the bearing in the tool, fill it with grease, and pump the handle until grease comes out the top.

Install the Inner Bearing and Seal

Place the packed inner bearing into the hub. Then, install a new oil seal. Use a seal driver or a socket that matches the seal’s outer diameter to tap it in evenly. Make sure it’s flush with the back of the hub.

Slide the Hub Onto the Spindle

Carefully slide the hub assembly back onto the spindle. Make sure it seats properly. Then, install the outer bearing into the hub.

Install the Spindle Nut and Adjust

Thread the spindle nut onto the spindle by hand. Tighten it with a wrench until there’s no play in the hub, then back it off slightly. The goal is to eliminate endplay without over-tightening.

For most trailers, the correct procedure is:

- Tighten the nut to 20–25 ft-lbs while spinning the hub.

- Back off the nut 1/4 to 1/2 turn.

- Re-tighten to 5–10 in-lbs (just snug).

- Insert a new cotter pin through the spindle and nut.

This process, called “bearing adjustment,” ensures the bearings are properly seated but not under excess pressure. Over-tightening causes heat buildup; under-tightening leads to wobble.

Reinstall the Dust Cap

Once the nut is secured, tap the dust cap back into place with a rubber mallet. If you’re using a bearing buddy system, make sure the grease zerk is accessible.

Reassembling and Final Checks

With the hub back on, it’s time to finish up and test your work.

Reinstall the Wheel

Place the wheel back onto the hub and hand-tighten the lug nuts. Lower the trailer from the jack stands, then torque the lug nuts in a star pattern to the manufacturer’s specification (usually 75–95 ft-lbs for most trailers).

Test the Wheel

Spin the wheel by hand. It should rotate smoothly with no grinding or resistance. Listen for unusual noises. Wiggle the wheel side to side—there should be minimal to no play.

Check for Heat After a Short Drive

Take the trailer for a short test drive (5–10 minutes). Then, feel the hub. It should be warm but not hot. If it’s too hot to touch, the bearings may be over-tightened.

Grease the Hub (If Using Bearing Buddy)

If your hub has a grease zerk, use a grease gun to add a small amount of grease. This pushes out old grease and ensures fresh lubrication.

Tips for Long-Term Bearing Health

Installing trailer bearings correctly is just the first step. To keep them in top shape, follow these maintenance tips:

Inspect Annually or Every 12,000 Miles

Make bearing maintenance part of your regular trailer upkeep. Even if you don’t tow often, moisture and corrosion can build up over time.

Use Marine-Grade Grease

If you tow near water or in wet conditions, marine-grade grease resists washout and protects against rust.

Install Bearing Buddies

These simple devices allow you to add grease without removing the hub. They also create pressure that helps keep water out.

Store Trailers Properly

When not in use, store your trailer under cover or use wheel chocks to prevent flat spots. If storing long-term, consider removing the wheels or using bearing protectors.

Watch for Warning Signs

Unusual noises, wobbling wheels, or excessive heat are red flags. Address them immediately to avoid bigger problems.

Common Mistakes to Avoid

Even experienced DIYers can make errors. Here are some common pitfalls:

Reusing Old Seals

Old seals harden and crack. Always install new ones to prevent leaks.

Over-Tightening the Spindle Nut

This is the #1 cause of bearing failure. Use a torque wrench and follow the adjustment procedure.

Skipping Grease Packing

Dry bearings overheat quickly. Always pack them fully.

Ignoring Rust or Pitting

Small rust spots can grow. Replace worn races and bearings—don’t just clean them.

Not Using Jack Stands

Safety first. Never work under a trailer supported only by a jack.

Conclusion

Installing trailer bearings might seem intimidating at first, but with the right tools and knowledge, it’s a manageable task for most DIYers. By following this guide, you’ll not only save money on shop fees but also gain confidence in maintaining your trailer’s safety and performance.

Remember: proper installation, regular maintenance, and attention to detail are the keys to long-lasting bearings. Take your time, double-check your work, and always prioritize safety. Whether you’re hauling a boat, camper, or equipment trailer, well-maintained bearings mean smoother rides and fewer surprises on the road.

So the next time your trailer needs new bearings, don’t panic—grab your tools, follow these steps, and get back to towing with peace of mind.

Frequently Asked Questions

How often should I replace trailer bearings?

Most experts recommend inspecting and repacking trailer bearings every 12,000 miles or once a year. Replace them if you notice wear, pitting, or excessive play.

Can I reuse old bearings if they look okay?

It’s not recommended. Even if bearings appear fine, internal damage or wear may not be visible. Always replace them during maintenance to ensure safety.

What type of grease should I use for trailer bearings?

Use high-temperature, water-resistant grease such as marine-grade or lithium-based grease. Avoid regular automotive grease, which can break down under heat and moisture.

How tight should the spindle nut be?

Tighten the spindle nut to 20–25 ft-lbs while spinning the hub, then back it off 1/4 to 1/2 turn. Final torque should be 5–10 in-lbs. Always use a torque wrench.

Why is my trailer wheel wobbling after installation?

Wobbling usually means the spindle nut is too loose or the bearings are damaged. Recheck the adjustment and inspect for wear.

Do I need special tools to install trailer bearings?

Basic tools like a socket set, torque wrench, and pliers are sufficient. A bearing packer and race installer are helpful but not required for occasional use.