Gear Wali Cycle Disc Brake: Smooth Rides

Gear Wali Cycle Disc Brake: Master Smooth, Confident Rides with This Essential Guide.

Key Takeaways:

Understand how gear wali cycle disc brakes improve stopping power.

Learn basic disc brake maintenance for optimal performance.

Identify common issues and simple fixes for your cycle.

Enjoy safer, smoother rides with well-maintained disc brakes.

When you’re out exploring the open roads or navigating city streets on your gear wali cycle, the last thing you want to worry about is your braking system. The smooth, reliable performance of disc brakes is a game-changer for any cyclist, offering superior stopping power and control, especially in challenging conditions. But what exactly makes them so effective, and how can you ensure yours are always in top shape? You might be curious about the technology behind these brakes, or perhaps you’ve noticed a slight change in their feel and want to know how to address it. This guide is here to demystify the gear wali cycle disc brake, providing you with clear, easy-to-follow advice to keep your rides smooth and your confidence high. Let’s dive into the world of disc brakes and discover how to get the best out of them.

In This Article

- 1 What is a Gear Wali Cycle Disc Brake System?

- 2 The Benefits of Gear Wali Cycle Disc Brakes

- 3 Essential Gear Wali Cycle Disc Brake Maintenance

- 4 Troubleshooting Common Gear Wali Cycle Disc Brake Issues

- 5 When to Seek Professional Help

- 6 Enhancing Your Ride with Disc Brake Upgrades

- 7 Understanding U.S. Regulations and Disc Brakes

- 8 Frequently Asked Questions About Gear Wali Cycle Disc Brakes

- 8.1 Q1: How often should I check my disc brake pads?

- 8.2 Q2: Can I use car brake cleaner on my bicycle disc brakes?

- 8.3 Q3: My disc brake rotor is rubbing. What should I do?

- 8.4 Q4: How do I know if my hydraulic disc brakes need bleeding?

- 8.5 Q5: Are disc brakes better than rim brakes for all types of cycling?

- 8.6 Q6: Do disc brakes make a lot of noise?

- 9 Conclusion

What is a Gear Wali Cycle Disc Brake System?

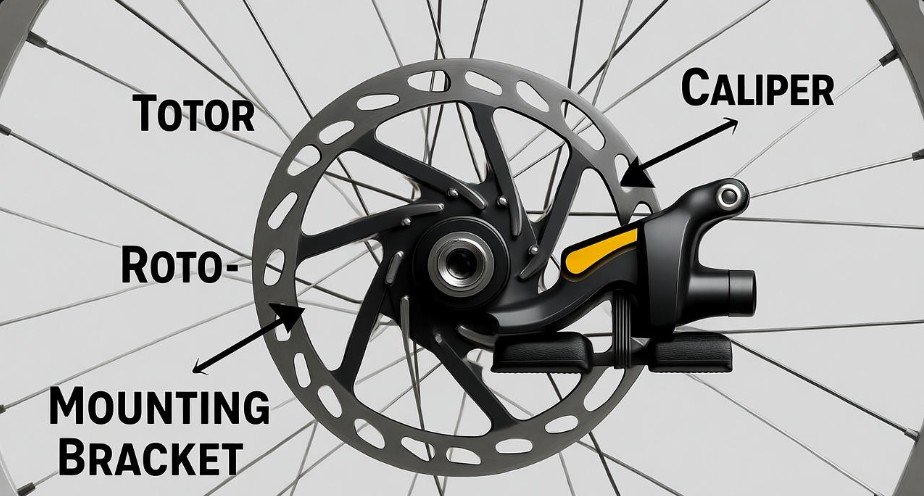

A gear wali cycle, often referred to as a geared bicycle, integrates multiple gears to make pedaling easier on varied terrain. When paired with disc brakes, these cycles offer a significantly enhanced riding experience. Unlike traditional rim brakes, which squeeze the wheel’s rim to slow down, disc brakes work with a rotor attached to the wheel hub and a caliper mounted to the frame or fork. This setup provides more consistent and powerful braking, regardless of weather conditions.

The system typically consists of a few key components:

- Brake Lever: Located on your handlebars; squeezing this lever activates the brake.

- Cable or Hose: Connects the lever to the caliper. For mechanical disc brakes, this is a steel cable. For hydraulic disc brakes, it’s a fluid-filled hose.

- Rotor: A metal disc attached to the wheel hub.

- Caliper: The mechanism that houses the brake pads and clamps onto the rotor.

- Brake Pads: Friction material that presses against the rotor to create stopping force.

Mechanical vs. Hydraulic Disc Brakes

Understanding the difference between mechanical and hydraulic disc brakes is crucial for proper maintenance and performance.

| Feature | Mechanical Disc Brakes | Hydraulic Disc Brakes |

|---|---|---|

| Actuation | Steel cable pulls a lever arm in the caliper. | Fluid pressure from lever pushes pistons in the caliper. |

| Power | Good stopping power, generally less than hydraulic. | Excellent stopping power and modulation (fine control). |

| Feel | Can feel a bit “spongy” or require more lever effort. | Firm, responsive lever feel. |

| Maintenance | Easier to adjust and repair with basic tools. Cable replacement is straightforward. | Requires bleeding to replace brake fluid, which can be more complex. |

| Cost | Generally less expensive. | Typically more expensive. |

| Performance in Wet Conditions | Good, but can be affected by cable contamination. | Excellent, as fluid is sealed from the elements. |

The Benefits of Gear Wali Cycle Disc Brakes

Disc brakes offer a noticeable improvement over older braking technologies, making your cycling experience safer and more enjoyable.

Superior Stopping Power

The primary advantage is their ability to generate more stopping force. This means you can slow down or stop much faster, which is vital for sudden situations or when riding downhill. This enhanced control inspires confidence, especially for newer cyclists.

Consistent Performance in All Weather

Unlike rim brakes, which rely on the rim’s surface and can be significantly degraded by mud, water, or ice, disc brakes perform reliably in diverse weather conditions. The braking surface is further away from the road and protected by the wheel, keeping it cleaner and drier.

Less Effort, More Control

Disc brakes, especially hydraulic systems, require less finger strength to operate effectively. This reduces hand fatigue on long rides and allows for finer modulation—meaning you can control your speed with greater precision, feathering the brakes for smooth deceleration rather than abrupt stops.

Reduced Wear on Rims

With rim brakes, the brake pads wear down the wheel’s rim over time. Disc brakes transfer this wear to the rotor and pads, leaving your wheel rims intact and extending the life of your wheels.

Essential Gear Wali Cycle Disc Brake Maintenance

Keeping your disc brakes in good working order is straightforward with regular, simple checks and maintenance. Following these steps will help ensure they function optimally for smooth, safe rides.

Regular Cleaning

Dirt, grime, and oil can contaminate your rotors and brake pads, reducing braking performance.

Rotor Cleaning: After a ride, especially if you’ve encountered mud or debris, use a clean cloth to wipe down the rotors. For a more thorough clean, spray isopropyl alcohol onto a clean cloth and wipe the rotor surface until it shines. Avoid touching the rotor surface with your bare hands, as skin oils can cause contamination.

Pad Inspection: Periodically check your brake pads for wear. Most pads have wear indicators, or you can visually inspect the thickness of the friction material. If they are worn down close to the metal backing, it’s time for a replacement.

Checking Brake Pad Wear

Brake pads are consumables, designed to wear out. Monitoring their condition is a key part of maintenance.

Visual Inspection: Remove the wheel and look at the brake pads within the caliper. You should be able to see a layer of friction material between the metal backing plate and the rotor. If this material is very thin (less than 1mm) or worn unevenly, it’s time to replace them.

Listen for Sounds: Squealing or grinding noises during braking can indicate worn-out pads or contamination. A gentle squeal might be normal if the pads are wet, but a consistent or loud noise is a warning sign.

Brake Pad Replacement

Replacing worn brake pads is a common maintenance task for any gear wali cycle owner. The process can vary slightly between brake models, but the general steps are similar.

Tools You Might Need:

- New brake pads compatible with your brake model

- Allen wrenches (usually a 4mm or 5mm)

- Torque wrench (recommended for precise tightening)

- Gloves (to keep pads clean)

- Brake pad spreader tool (or a clean, flathead screwdriver)

Steps for Replacement:

1. Remove the Wheel: This gives you better access to the caliper.

2. Open the Caliper:

For many systems, you’ll need to remove a small retaining pin or clip that holds the brake pads in place.

You may then need to gently push the brake pads apart to create enough space to remove them. This is where a pad spreader tool or a flathead screwdriver can be useful, being careful not to damage the caliper. For hydraulic brakes, you might need to push the pistons back slightly.

3. Remove Old Pads: Slide or pull the old brake pads out of the caliper.

4. Clean the Caliper: Use a clean cloth to wipe away any dust or debris inside the caliper body.

5. Install New Pads: Slide the new brake pads into position. Ensure they are oriented correctly according to the manufacturer’s instructions.

6. Reassemble: Reinstall any retaining pins or clips.

7. Center the Caliper: If the pads are rubbing on the rotor, you may need to adjust the caliper’s position. Loosen the caliper mounting bolts slightly, squeeze the brake lever firmly, and while holding the lever, re-tighten the bolts.

8. Reinstall the Wheel: Put the wheel back on the bike.

9. Bed In New Pads: This is a critical step! New pads need to “bed in” to the rotor to achieve optimal performance. Ride the bike and perform several moderate-speed stops, gradually increasing intensity. On a safe, open stretch, accelerate to a moderate speed (e.g., 10-15 mph) and brake firmly but without locking up the wheels. Repeat this 10-20 times. This process transfers a thin layer of pad material to the rotor, creating a more uniform braking surface.

Bleeding Hydraulic Disc Brakes

If your hydraulic disc brakes feel spongy or less powerful, they may need to be bled. This process removes air bubbles from the brake lines and replaces old fluid with fresh fluid. Bleeding kits are available from various bicycle brands, and many components use DOT fluid or mineral oil.

Important Note: Bleeding hydraulic brakes can be a bit more complex than basic maintenance. If you’re not comfortable with the process, it’s best to have a professional mechanic at a local bike shop perform this service. Improper bleeding can lead to brake failure. For guidance on specific brake systems, consult the manufacturer’s website or official service manuals. For example, Shimano and SRAM, major manufacturers of bicycle components, provide detailed instructions for their brake systems on their respective websites.

Troubleshooting Common Gear Wali Cycle Disc Brake Issues

Even with regular maintenance, you might encounter minor issues. Here are some common problems and how to address them.

Squealing Brakes

Cause: Contaminated pads or rotors, glazed pads, loose rotor bolts, or warped rotor.

Solution:

Clean rotors with isopropyl alcohol.

Inspect and clean or replace brake pads.

Check that rotor bolts are tight and torqued correctly (use a torque wrench if possible).

If the rotor is warped, it may need to be straightened or replaced.

Spongy Brake Lever

Cause: Air in the hydraulic lines, worn seals, or low fluid level.

Solution:

For hydraulic brakes, bleeding the system is usually required.

For mechanical brakes, check cable tension and condition; replace cable if frayed or corroded.

Brakes Not Stopping Effectively

Cause: Contaminated pads/rotors, worn pads, cable stretch (mechanical), air in the system (hydraulic), or improperly bedded-in new pads.

Solution:

Clean rotors and replace pads if worn.

For mechanical brakes, adjust cable tension.

For hydraulic brakes, bleed the system.

Re-bed new or cleaned pads to the rotor.

Rotor Rubbing

Cause: Caliper is out of alignment, minor rotor warp, or wheel is not seated correctly.

Solution:

Re-align the caliper by loosening the mounting bolts, squeezing the brake lever, and re-tightening the bolts.

Ensure the rotor is true (not bent).

Check that the wheel is properly seated in the dropouts.

When to Seek Professional Help

While many disc brake issues can be resolved with basic home maintenance, some problems require specialized knowledge or tools.

Persistent Squealing: If cleaning and pad replacement don’t solve squealing.

Brake Fade: A significant loss of braking power, especially during long descents.

Spongy Lever That Won’t Improve: If bleeding doesn’t fix the issue.

Damaged Rotors or Calipers: Visible bends, cracks, or damage.

Uncertainty: If you’re unsure about any step in the maintenance or repair process.

A visit to your local bike shop ensures your gear wali cycle disc brakes are serviced by experienced technicians who have the right tools and parts. They can also perform a complete safety check of your entire braking system.

Pro Tip: Always perform a quick brake check by squeezing the levers firmly before every ride to ensure you have solid engagement and no unexpected softness.

Enhancing Your Ride with Disc Brake Upgrades

If you’ve been riding for a while and want to elevate your gear wali cycle’s performance, upgrading your disc brakes is a fantastic option.

Better Rotors

Upgrading your rotors can offer improved heat dissipation, potentially reducing brake fade on long descents. Some rotors are also designed to be lighter or offer better mud-shedding capabilities.

Higher-Quality Brake Pads

Different brake pad compounds offer varying benefits:

- Resin (Organic): Quieter, easier on rotors, good initial bite, but wear faster and perform poorly in wet/muddy conditions.

- Metallic (Sintered): More durable, perform better in wet/muddy conditions, but can be noisier and wear rotors faster.

- Semi-Metallic: A balance between resin and metallic, offering a good compromise in performance and durability.

Choosing the right pad compound for your riding style and environment can make a significant difference.

Full Hydraulic Systems

If your current gear wali cycle has mechanical disc brakes, upgrading to a full hydraulic system can provide a dramatic improvement in stopping power and lever feel. This is often a more involved upgrade but can transform the riding experience.

Understanding U.S. Regulations and Disc Brakes

While there are no specific federal regulations in the USA mandating disc brakes on bicycles, or dictating their standards, ensuring your brakes are in good working order is a matter of personal safety and is implicitly covered by general traffic laws that require functioning safety equipment. Organizations like the Bicycle Association and the U.S. Consumer Product Safety Commission (CPSC) offer general guidelines on bicycle safety equipment, emphasizing the importance of reliable braking. For instance, the CPSC recommends that bicycles be equipped with brakes that can stop the bike within a specified distance under normal conditions. Always ensure your braking system meets your personal safety standards and local cycling community best practices.

Frequently Asked Questions About Gear Wali Cycle Disc Brakes

Q1: How often should I check my disc brake pads?

It’s recommended to visually inspect your brake pads at least once a month, or more frequently if you ride often or in harsh conditions. Listen for any new noises during braking.

Q2: Can I use car brake cleaner on my bicycle disc brakes?

No, it’s best to use isopropyl alcohol or a dedicated bicycle brake cleaner. Car brake cleaners may contain chemicals that can damage your brake pads or rotors.

Q3: My disc brake rotor is rubbing. What should I do?

This usually means the brake caliper is misaligned. Loosen the caliper mounting bolts, squeeze the brake lever firmly, and while holding the lever, re-tighten the bolts. Ensure the wheel is also seated correctly.

Q4: How do I know if my hydraulic disc brakes need bleeding?

If your brake lever feels spongy, goes all the way to the handlebar without engaging strongly, or you notice a significant decrease in braking power, it’s likely time to bleed the system.

Q5: Are disc brakes better than rim brakes for all types of cycling?

For most types of cycling, especially mountain biking, gravel riding, commuting in varied weather, and downhill riding, disc brakes offer superior performance. For very light road cycling in dry conditions, high-quality rim brakes can still be adequate, but disc brakes are generally considered more advanced and reliable.

Q6: Do disc brakes make a lot of noise?

New brake pads can sometimes be a bit noisy until they are bedded in. Contaminated pads or rotors are a common cause of consistent squealing or grinding. Ensuring proper setup and keeping components clean usually resolves most noise issues.

Conclusion

The gear wali cycle disc brake system is a cornerstone of modern cycling safety and performance. By understanding how these brakes work, performing regular, straightforward maintenance, and knowing when to seek professional assistance, you can ensure your bicycle delivers smooth, confident rides every time. From mastering the simple cleaning routines to understanding the nuances of pad replacement and hydraulic systems, this guide equips you with the knowledge to keep your disc brakes in peak condition. Embrace the superior stopping power and control that disc brakes offer, and enjoy every mile of your cycling journey with enhanced safety and peace of mind.