Brake Booster and Master Cylinder: Your Guide

Your brake booster and master cylinder are vital components for safe braking. This guide explains their function, common problems, and how they work together to help you understand your car’s braking system better.

In This Article

- 1 Key Takeaways

- 2 Understanding Your Brake Booster and Master Cylinder: The Braking Duo

- 3 How the Brake Booster and Master Cylinder Work Together

- 4 Diagnosing Brake Issues: Booster vs. Master Cylinder

- 5 Maintenance and Longevity

- 6 Replacing the Brake Booster and Master Cylinder

- 7 Frequently Asked Questions (FAQ)

- 7.1 What happens if my brake booster fails while driving?

- 7.2 Can I drive with a failing master cylinder?

- 7.3 How often should my brake fluid be changed?

- 7.4 Is it possible to have a leak from both the brake booster and master cylinder?

- 7.5 What is the difference between vacuum-assisted and hydro-boost braking systems?

- 7.6 How can I check if my brake booster is leaking vacuum?

- 7.7 What are the signs of worn brake pads versus a master cylinder issue?

- 8 Conclusion

Key Takeaways

- Understand the roles of your brake booster and master cylinder.

- Identify signs of a failing brake booster.

- Recognize symptoms of a faulty master cylinder.

- Learn how these parts work in tandem for braking.

- Grasp the importance of their maintenance for safety.

Feeling unsure about your car’s braking system? You’re not alone. Many drivers hear terms like “brake booster” and “master cylinder” and wonder what they do. These two parts are the unsung heroes of your car’s ability to stop safely. They work together to make pressing the brake pedal feel easy, even though you’re commanding significant stopping power. If they aren’t working right, your braking can feel hard, spongy, or even fail. This guide will break down what the brake booster and master cylinder are, how they function, and what to look for if you suspect a problem. Let’s dive in and demystify your car’s brakes!

Understanding Your Brake Booster and Master Cylinder: The Braking Duo

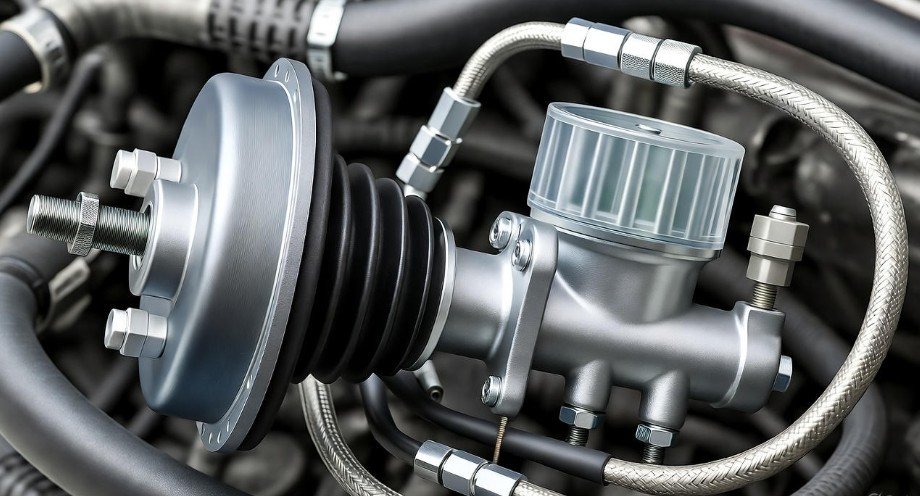

At the heart of your car’s braking system lie two critical components: the brake booster and the master cylinder. They are essential for ensuring that when you press your brake pedal, your vehicle slows down effectively and safely. Without them, braking would require immense physical effort, making driving impractical and dangerous. Understanding their individual roles and how they collaborate is fundamental to any car owner’s knowledge. Think of them as a team, each with a specific job, but both working towards the same goal: stopping your car.

What is a Brake Booster? The Power Assist

The brake booster, also known as the vacuum booster or power brake booster, is a device that amplifies the force you apply to the brake pedal. Imagine trying to stop a multi-ton vehicle using only the strength of your leg – it would be nearly impossible! The brake booster uses the engine’s vacuum (or in some modern cars, an electric pump) to create this amplification. When you press the brake pedal, a valve inside the booster opens, allowing engine vacuum to push a diaphragm. This push significantly multiplies the force you exert, sending it to the master cylinder. This is why even small cars are easy to stop with a gentle press of the pedal.

How the Brake Booster Works

The operation of a vacuum brake booster is a clever interplay of atmospheric pressure and engine vacuum:

- Pedal Pressed: When you step on the brake pedal, it moves a pushrod connected to a valve inside the booster.

- Vacuum and Air Control: This valve controls the flow of vacuum from the engine and atmospheric air into the booster’s chamber.

- Diaphragm Movement: As the valve shifts, it allows engine vacuum to enter one side of a diaphragm, while the other side is exposed to atmospheric pressure. The difference in pressure pushes the diaphragm.

- Force Amplification: The diaphragm’s movement is connected to another pushrod that then acts upon the master cylinder, providing the amplified force.

- Pedal Released: When you release the brake pedal, the valve closes off the vacuum and air passages, equalizing the pressure on both sides of the diaphragm and stopping the assistance.

This process happens almost instantaneously, providing a smooth and responsive braking experience. For a deeper dive into automotive vacuum systems, resources like the U.S. Department of Energy’s explanation of internal combustion engines can provide context on how vacuum is generated.

Common Brake Booster Problems

A failing brake booster can manifest in several noticeable ways, indicating a need for immediate attention. Because it’s directly tied to your car’s ability to stop, ignoring these signs can be dangerous.

- Hard Brake Pedal: This is the most common symptom. If you have to press much harder than usual to get the brakes to engage, the booster might not be providing its assist.

- Spongy or Spongy Brake Pedal: While often associated with air in the brake lines or a master cylinder issue, a compromised booster diaphragm can also contribute to a spongy feel.

- Hissing Noise from Under the Hood: A vacuum leak in the booster or its connecting hoses can often be heard as a distinct hissing sound, especially when the engine is running.

- Brakes Apply Themselves: If the booster’s internal valve gets stuck, it can sometimes cause the brakes to drag or even apply slightly without you touching the pedal.

- Brake Warning Light: In some vehicles, a malfunctioning brake booster can trigger the brake warning light on your dashboard.

These symptoms are crucial indicators that your brake booster may be compromised, and it’s wise to have it inspected by a qualified mechanic.

What is a Master Cylinder? The Hydraulic Heart

The master cylinder is the control center of your car’s hydraulic braking system. It’s essentially a powerful pump that converts the mechanical force from your brake pedal (amplified by the brake booster) into hydraulic pressure. This hydraulic pressure is then transmitted through brake lines filled with brake fluid to the brake calipers (on disc brakes) or wheel cylinders (on drum brakes) at each wheel. These components then force the brake pads against the rotors or the brake shoes against the drums, slowing and stopping your vehicle.

How the Master Cylinder Works

The master cylinder is a relatively simple yet robust device, typically containing one or two pistons within a cylinder, along with reservoirs to hold brake fluid. Here’s a simplified breakdown of its operation:

- Brake Fluid Reservoirs: The master cylinder has one or two reservoirs that store the brake fluid. These reservoirs ensure there’s always enough fluid available to operate the system.

- Piston(s) and Cylinders: Inside the cylinder bore(s) are one or two pistons. The brake pedal’s force (assisted by the booster) pushes these pistons forward.

- Hydraulic Pressure Generation: As the pistons move, they displace the brake fluid. Because brake fluid is practically incompressible, this displacement creates immense hydraulic pressure within the system.

- Dual-Circuit Braking: Modern vehicles almost universally employ a dual-circuit braking system for safety. This means the master cylinder typically has two separate reservoirs and two pistons, so if one circuit fails (e.g., a brake line breaks), the other can still provide some braking force. Typically, one circuit operates the front brakes and the other the rear, or one operates diagonal wheels.

- Return Springs: When you release the brake pedal, return springs push the pistons back to their resting position, relieving the hydraulic pressure.

The integrity of the master cylinder is paramount. Internal seals can wear out, leading to leaks or a bypass of hydraulic pressure, significantly impacting braking performance. For more on brake fluid types and their importance, check out resources from the National Highway Traffic Safety Administration (NHTSA), such as their vehicle recall and safety information, which often highlight the impact of fluid issues.

Common Master Cylinder Problems

A failing master cylinder is another serious safety concern. Recognizing its symptoms is crucial for prompt repair:

- Spongy or Soft Brake Pedal: This is a classic sign. If the pedal feels mushy and sinks towards the floor when you press it, it often indicates an internal leak within the master cylinder or air in the brake lines.

- Brakes Sinking to the Floor: If the brake pedal slowly sinks to the floor while you are holding pressure on it, the master cylinder is likely bypassing fluid internally.

- Low Brake Fluid Level: While a low fluid level can be due to worn brake pads (which is normal), a consistently dropping level without obvious external leaks might point to an internal leak in the master cylinder.

- Brake Warning Light: A low brake fluid level or a pressure differential in the dual-circuit system will often illuminate the brake warning light on your dashboard.

- Leaking Brake Fluid: You might observe brake fluid leaking from the master cylinder itself, usually around the seals where it connects to the brake lines or from the reservoir.

If you notice any of these signs, it’s important to have your braking system inspected by a professional immediately.

How the Brake Booster and Master Cylinder Work Together

The synergy between the brake booster and the master cylinder is what makes modern braking systems so effective and user-friendly. They don’t operate in isolation; rather, they form a critical chain of command:

1. Driver Input: You press the brake pedal.

2. Booster Amplification: The brake booster uses engine vacuum (or an electric pump) to multiply the force you applied to the pedal.

3. Pushrod Action: The amplified force is transferred via a pushrod from the booster to the master cylinder.

4. Hydraulic Pressure: The master cylinder converts this mechanical force into hydraulic pressure within the brake fluid.

5. Fluid Transmission: This hydraulic pressure travels through the brake lines to the wheel brakes.

6. Braking Action: The wheel brakes (calipers or wheel cylinders) actuate, applying pressure to slow or stop the vehicle.

This seamless collaboration is why a light press of your brake pedal can stop a heavy vehicle. If either component fails, the chain is broken, and braking performance is severely compromised.

Diagnosing Brake Issues: Booster vs. Master Cylinder

Distinguishing between a brake booster problem and a master cylinder problem can sometimes be tricky, as some symptoms overlap. However, there are key differences that can help in diagnosis:

Brake Booster Symptoms Checklist

- Pedal Feel: Primarily a very hard pedal that requires significant effort.

- Noise: Often accompanied by a hissing sound related to vacuum leaks.

- Assistance: The primary issue is the lack of power assist.

Master Cylinder Symptoms Checklist

- Pedal Feel: Primarily a soft, spongy, or sinking pedal.

- Fluid Level: May show a consistently dropping brake fluid level.

- Engagement: The issue is often with the generation or holding of hydraulic pressure.

Table: Differentiating Brake Booster and Master Cylinder Failures

| Symptom | Likely Brake Booster Issue | Likely Master Cylinder Issue |

|---|---|---|

| Brake Pedal is Very Hard to Press | Yes (loss of vacuum assist) | Rarely (unless fluid is extremely low, then it might feel slightly harder) |

| Brake Pedal Feels Spongy or Soft | Sometimes (can contribute) | Yes (internal leaks, air in lines) |

| Brake Pedal Sinks to the Floor | No (unless it also causes a leak) | Yes (internal bypass of fluid) |

| Hissing Noise When Braking/Engine Running | Yes (vacuum leak) | No |

| Brake Warning Light Illuminates | Sometimes (especially vacuum issues) | Yes (low fluid or pressure differential) |

| Brake Fluid Level Drops Consistently | Rarely (unless a hose connected to it leaks) | Yes (internal or external leaks from the cylinder) |

It’s important to note that these are general guidelines. A professional mechanic has the tools and experience to accurately diagnose the specific cause of your braking issues.

Maintenance and Longevity

Both the brake booster and master cylinder are designed to be robust, but they are not immune to wear and tear. Proper maintenance can help extend their lifespan and ensure your braking system remains reliable.

Brake Booster Maintenance

The brake booster itself requires little direct maintenance. Its longevity relies heavily on the health of the engine and the integrity of its vacuum source. Key factors include:

- Vacuum Hoses: Regularly inspect the vacuum hoses connecting the engine to the brake booster for cracks, kinks, or loose connections. A compromised hose means a compromised vacuum source.

- Engine Health: A healthy engine that idles smoothly and produces consistent vacuum is crucial for proper booster operation.

- Brake Fluid: While not directly affecting the booster’s internal mechanics, keeping the brake fluid at the correct level ensures the master cylinder can function, which in turn allows the booster to do its job effectively.

Master Cylinder Maintenance

Maintenance for the master cylinder primarily revolves around the brake fluid it contains and the seals within it.

- Brake Fluid Flushes: Brake fluid is hygroscopic, meaning it absorbs moisture over time. This moisture can corrode internal brake system components, including the master cylinder seals. Following your vehicle manufacturer’s recommended schedule for brake fluid flushes (often every 2-3 years) is vital. For information on brake fluid, consult the EPA’s Fuel Economy website which often discusses vehicle maintenance best practices.

- Brake Fluid Level Checks: Regularly check the brake fluid level in the master cylinder reservoir. If it’s consistently low, it could indicate leaks that need addressing before they worsen.

- Inspection for Leaks: Visually inspect the master cylinder and the connections to the brake lines for any signs of fluid leakage.

Pro Tip:

When checking your brake fluid, always use the correct type of fluid specified in your owner’s manual. Mixing different types of brake fluid can damage your braking system.

Replacing the Brake Booster and Master Cylinder

Replacing a brake booster or master cylinder is a significant automotive repair. It involves working with your car’s critical safety system and often requires specialized tools and knowledge.

When to Consider Replacement

Replacement is necessary when either component exhibits the symptoms of failure discussed earlier and diagnosis confirms it as the faulty part. Ignoring these symptoms is hazardous and can lead to accidents.

The Replacement Process (Beginner Overview)

While a DIY replacement is possible for experienced mechanics, it’s often best left to professionals for safety reasons. Here’s a general overview:

Brake Booster Replacement Steps:

- Safety First: Ensure the vehicle is safely supported on jack stands.

- Disconnect Battery: Always disconnect the negative battery terminal to prevent electrical issues.

- Access the Booster: This typically involves removing components under the hood, such as the air intake system or battery tray, to reach the firewall where the booster is mounted.

- Disconnect Master Cylinder: Unbolt the master cylinder from the brake booster. Be prepared for brake fluid spillage – have rags and a drain pan ready.

- Remove Old Booster: Unbolt the brake booster from the firewall (from inside the vehicle, often behind the brake pedal assembly).

- Install New Booster: Mount the new booster to the firewall.

- Reattach Master Cylinder: Bolt the master cylinder back onto the new booster. Ensure seals are properly seated.

- Bleed the Brakes: This is a critical step to remove all air from the brake lines and ensure proper hydraulic pressure.

- Reconnect Components and Test: Reassemble any removed parts, reconnect the battery, and meticulously test the brake pedal feel and stopping power in a safe area.

Master Cylinder Replacement Steps:

- Safety First: Vehicle supported on jack stands.

- Disconnect Battery: Disconnect the negative battery terminal.

- Drain Brake Fluid: Siphon or drain fluid from the master cylinder reservoir.

- Disconnect Brake Lines: Carefully unbolt the brake lines from the master cylinder. Again, expect fluid spillage.

- Remove Old Master Cylinder: Unbolt the master cylinder from the brake booster or firewall mounting.

- Install New Master Cylinder: Mount the new cylinder, ensuring seals are correctly positioned.

- Reconnect Brake Lines: Reattach the brake lines. Ensure they are tightened to the correct specifications.

- Fill with Fluid and Bleed: Fill the reservoir with fresh, correct-type brake fluid and bleed the entire brake system thoroughly.

- Test Brakes: Reassemble, reconnect the battery, and test the pedal feel and stopping power.

Note: Brake bleeding is a crucial step for both replacements. It involves systematically forcing brake fluid through the lines to expel any trapped air. Air in the brake lines is compressible, which is why it leads to a soft or spongy pedal. For detailed instructions on bleeding brakes, reputable automotive repair guides or websites like AutoZone’s repair guides offer step-by-step procedures.

Frequently Asked Questions (FAQ)

What happens if my brake booster fails while driving?

If your brake booster fails while driving, your brake pedal will become extremely hard, requiring significantly more force to press. While your brakes will still function, they will be very difficult to engage effectively, drastically increasing your stopping distance. It’s crucial to pull over safely as soon as possible and have the vehicle towed.

Can I drive with a failing master cylinder?

Driving with a failing master cylinder is extremely dangerous. Symptoms like a spongy or sinking pedal mean your brakes are not reliably engaging. Your stopping distance will be much longer, and in severe cases, your brakes may fail entirely. It is not safe to drive in this condition.

How often should my brake fluid be changed?

Most manufacturers recommend changing brake fluid every 2 to 3 years, or based on mileage, whichever comes first. This helps prevent corrosion and ensures optimal performance of your braking system components, including the master cylinder.

Is it possible to have a leak from both the brake booster and master cylinder?

While less common, it is possible. A significant leak from the seal between the master cylinder and brake booster could affect both. However, typically, if the booster has a vacuum leak, it won’t cause a brake fluid leak. Conversely, a master cylinder fluid leak could potentially contaminate the booster diaphragm, leading to its failure over time.

What is the difference between vacuum-assisted and hydro-boost braking systems?

Vacuum-assisted braking is the most common type, using engine vacuum. Hydro-boost braking systems use power steering pump pressure to assist braking. Hydro-boost systems generally provide more assist than vacuum boosters and are often found on larger vehicles like trucks and SUVs, or in applications where engine vacuum might be inconsistent.

How can I check if my brake booster is leaking vacuum?

Listen for a hissing sound from the engine bay when the engine is running. You can also try turning off the engine, pumping the brake pedal several times until it becomes very hard, and then holding firm pressure on the pedal. Start the engine. If the pedal sinks slightly, the booster is likely holding vacuum. If the pedal remains hard, there might be an issue with the booster or its vacuum supply.

What are the signs of worn brake pads versus a master cylinder issue?

Worn brake pads typically cause a grinding or squealing noise when braking, and may result in a slightly longer pedal, but the pedal itself usually remains firm. A master cylinder issue, on the other hand, typically results in a spongy, soft, or sinking pedal feel, even if the brake pads are in good condition.

Conclusion

Your vehicle’s brake booster and master cylinder are indispensable components that ensure your safety on the road. Understanding their functions – the booster providing the power assist and the master cylinder generating the hydraulic pressure – is key to recognizing when something isn’t right. Symptoms like a hard, spongy, or sinking brake pedal, along with unusual noises or fluid leaks, are clear indicators that these vital parts may be failing. Regular maintenance, particularly ensuring the correct brake fluid is used and changed on schedule, is your best defense against premature wear. While experienced drivers might tackle some repairs, the safety-critical nature of the braking system often makes professional diagnosis and repair the most prudent choice. By staying informed about your car’s braking system, you empower yourself to drive with greater confidence and peace of mind.